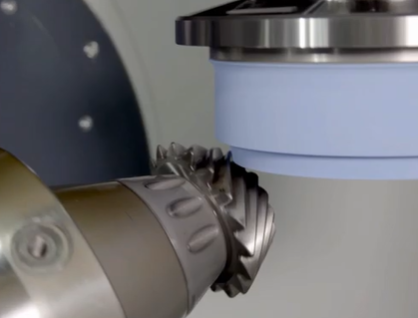

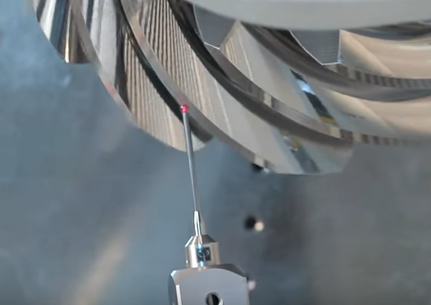

Peb cov txheej txheem spiral bevel iav tsav cov kev daws teeb meem tau tsim los ua kom muaj txiaj ntsig zoo, tshwj xeeb yog tsim rau kev lag luam uas xav tau qhov tseeb thiab kev ntseeg siab, xws li cov neeg hlau, cov tubrog nkoj, thiab lub zog tauj dua tshiab.Cov cuab yeej txiav-ntug no tau ua tib zoo tsim los ntawm cov khoom siv hnyav tsis tau tshwj xeeb, nrog rau qib siab aluminium thiab titanium alloys.Kev tsim kho tshiab ntawm cov iav no ua kom tsis muaj qhov sib piv ntawm kev hloov pauv torque, teeb tsa cov qauv tshiab rau kev ua haujlwm zoo hauv qhov chaw muaj zog thiab xav tau.

Yuav ua li cas cov ntaub ntawv yuav muab rau cov neeg muas zaub ua ntej shipping rau sib tsoo loj kauv bevel iav?

1) npuas kos duab

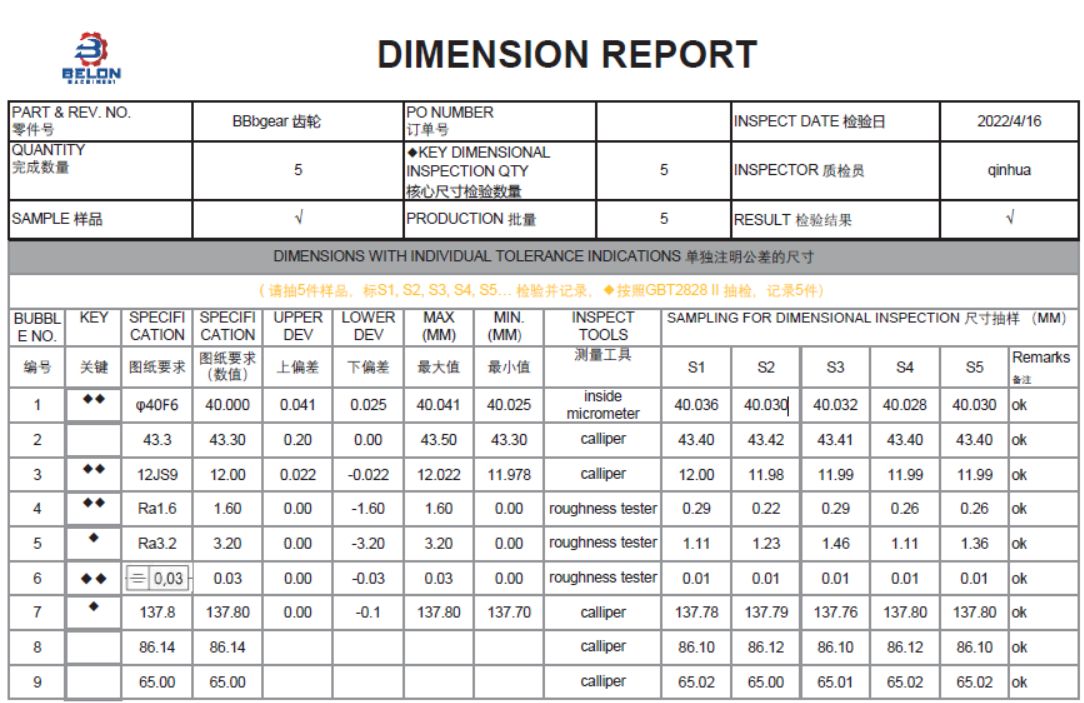

2) Dimension daim ntawv qhia

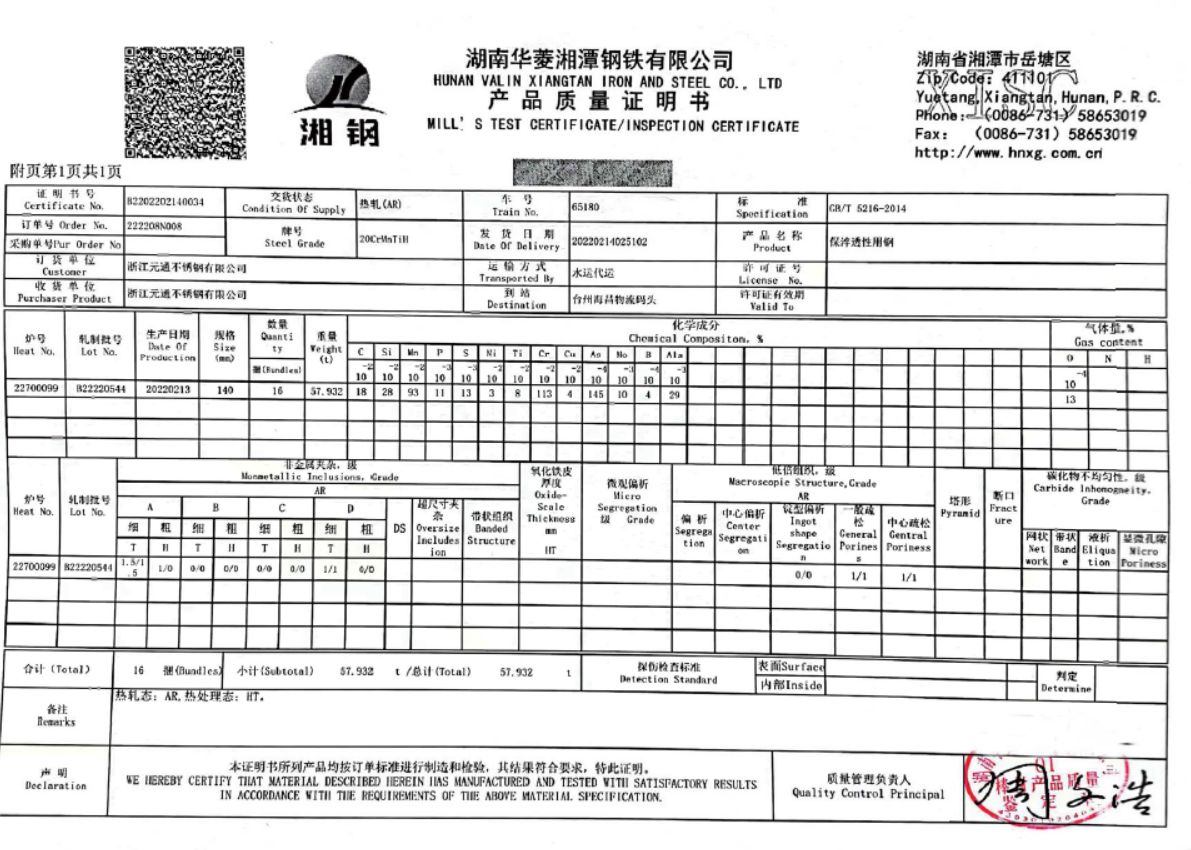

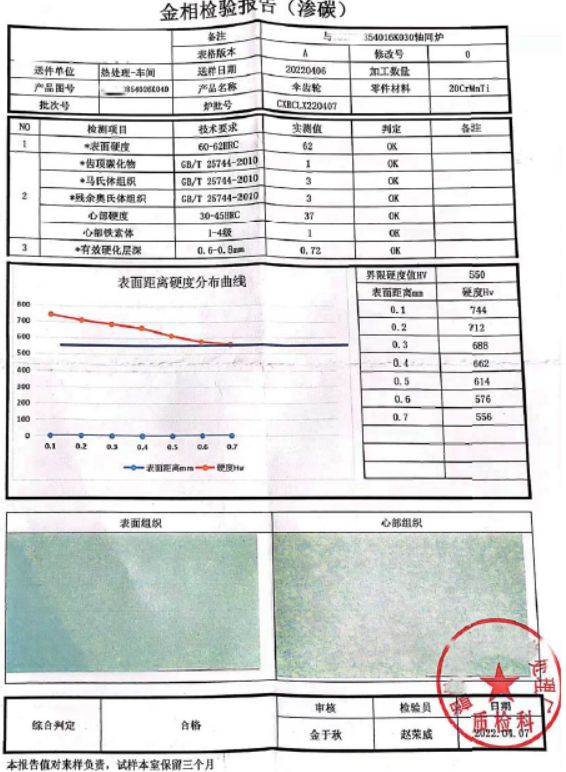

3) Cov ntaub ntawv pov thawj

4) Daim ntawv qhia txog kev kho cua sov

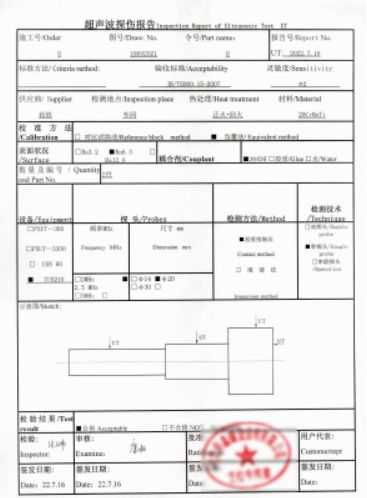

5) Ultrasonic Test Report (UT)

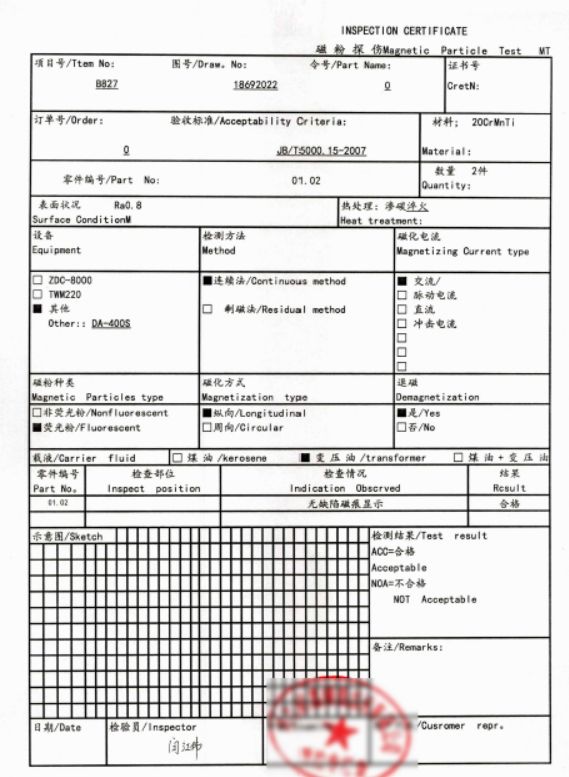

6) Magnetic Particle Test Report (MT)

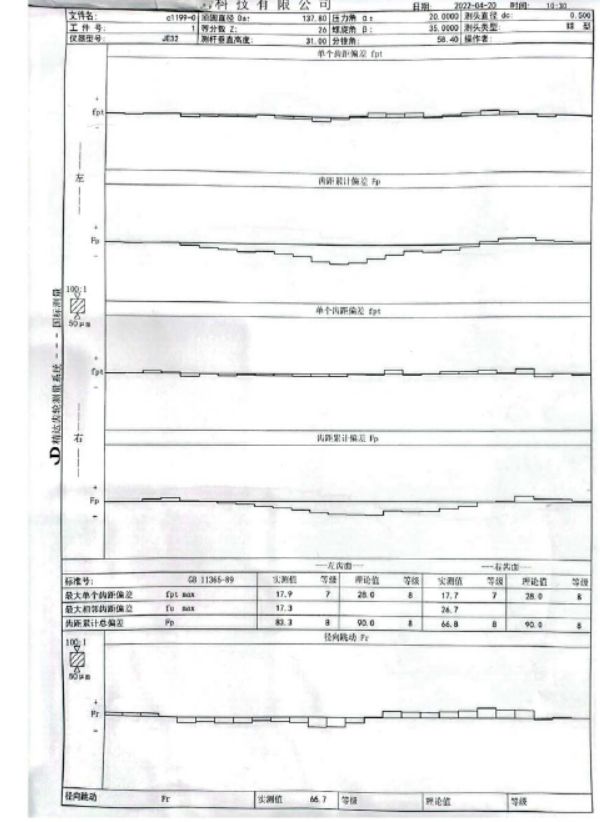

Meshing test report

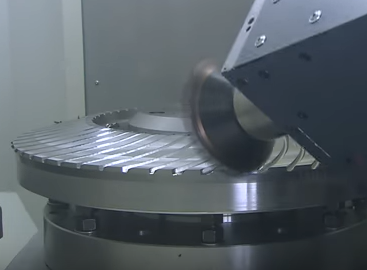

Peb converts thaj tsam ntawm 200000 square meters, kuj nruab nrog ua ntej ntau lawm thiab soj ntsuam cov khoom kom tau raws li cov neeg xav tau.Peb tau qhia txog qhov loj tshaj plaws, Tuam Tshoj thawj lub iav tshwj xeeb Gleason FT16000 tsib-axis machining chaw txij li kev koom tes ntawm Gleason thiab Holler.

→ Txhua Module

→ Txhua tus lej ntawm cov hniav

→ Qhov tseeb tshaj plaws DIN5

→ High efficiency, siab precision

Nqa cov npau suav tsim khoom, yooj yim thiab kev lag luam rau cov khoom me me.

raw khoom

ntxhib txiav

tig

quenching thiab tempering

iav milling

Kub kho

iav milling

kuaj