Cov hom bevel iav teeb no yog siv rau ntawm hom gearmotors thiab qee yam ntawm lawv yog hom ., nrog lub suab qis thiab siab hnav-resistant .

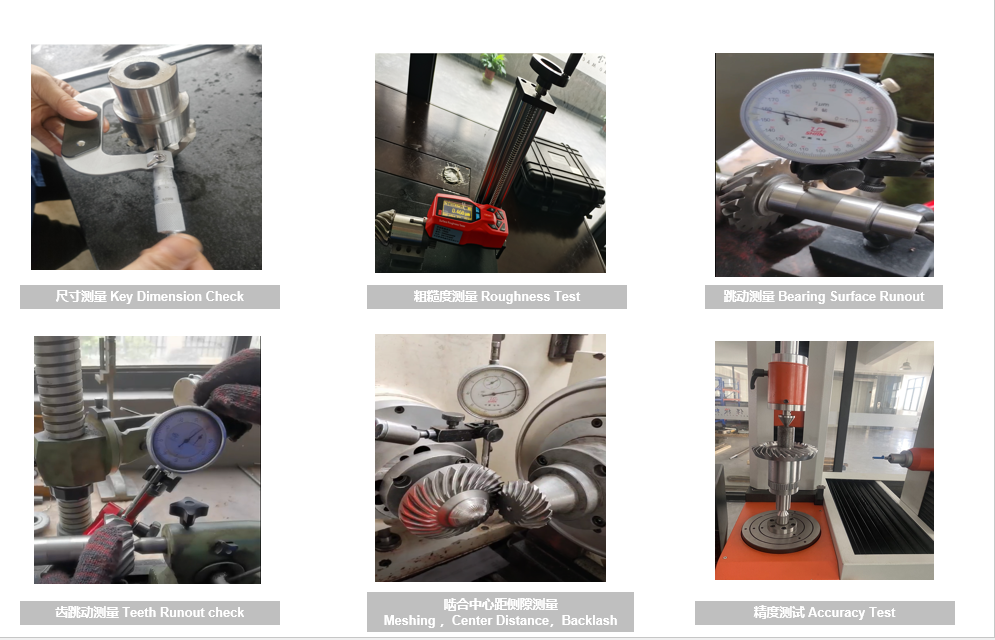

Cov ntaub ntawv tseem ceeb rau cov hom bevel iav yog:

1) Dimension daim ntawv qhia (ntxiv rau bearing nto runout kuaj video)

2) Cov ntaub ntawv qhia ua ntej kev kho cua sov

3) Heat Treat report ntxiv hardness thiab Metallographic

4) Cov ntaub ntawv xeem raug

5) Meshing Test daim ntawv qhia (ntxiv rau qhov chaw nrug, rov qab ntsuas cov yeeb yaj kiab)

Cov txheej txheem ntau lawm rau cov hom bevel iav teeb yog raws li hauv qab no:

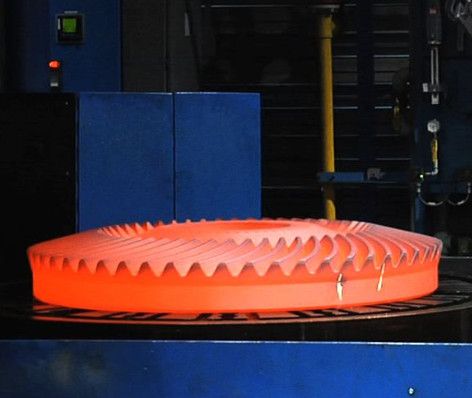

1) Forging

2) Rough txiav

3) Lub iav tig

4) quenching thiab tempering kub kho

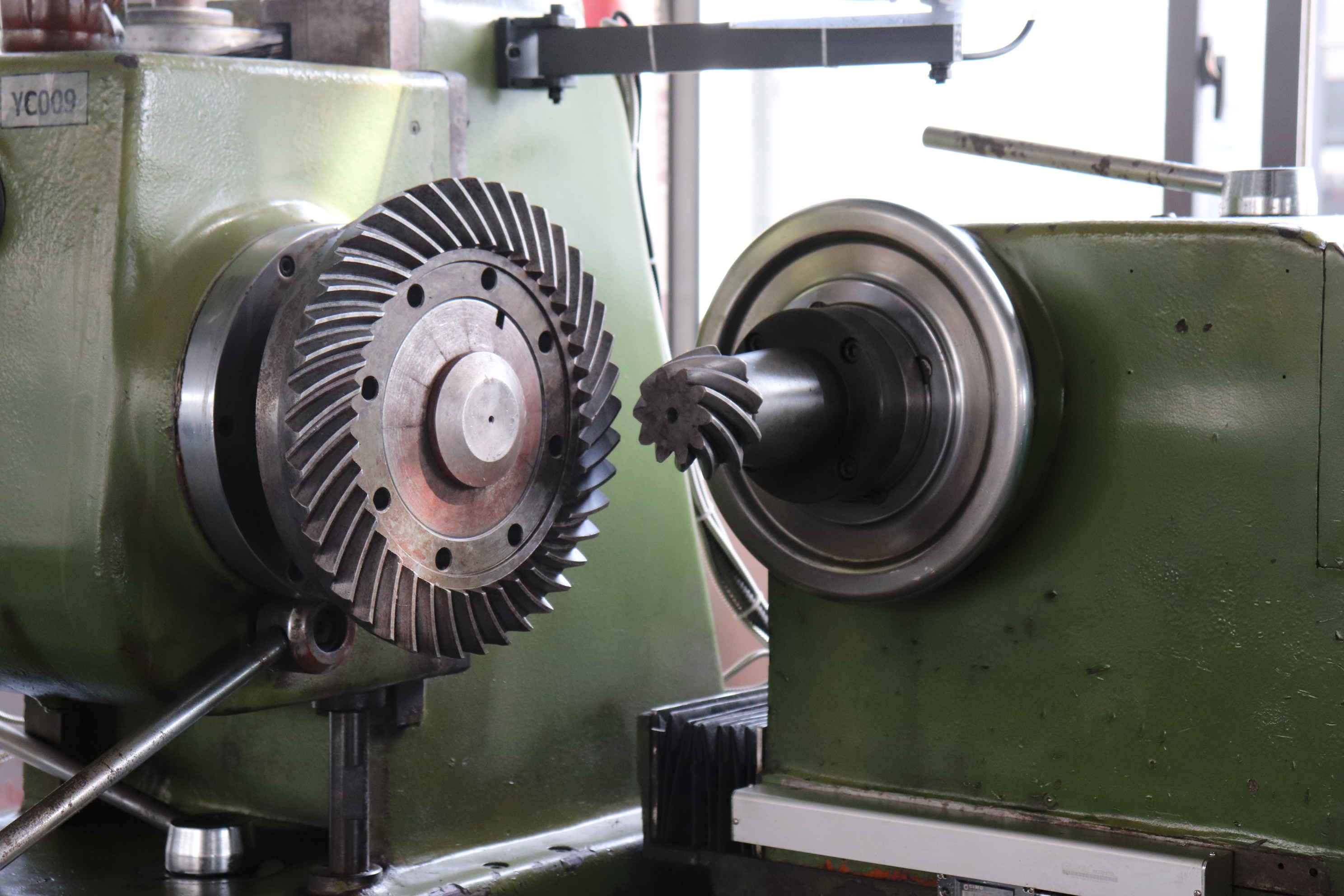

5) Gear milling rau teeh

6) Kev kho cua sov zoo li carburizing

7) Gear Lapping txhawm rau txhim kho cov iav nto zoo

8) Ua tiav kev tshuaj xyuas

Peb npog thaj tsam ntawm 25 ev kawj thiab lub tsev thaj tsam ntawm 26,000 square meters, kuj tau nruab nrog cov khoom ua ntej thiab tshuaj xyuas kom tau raws li cov neeg siv khoom sib txawv.

Forging

Tshuab dhos tig

Milling

Kev kho cua sov

OD / ID sib tsoo

Lapping

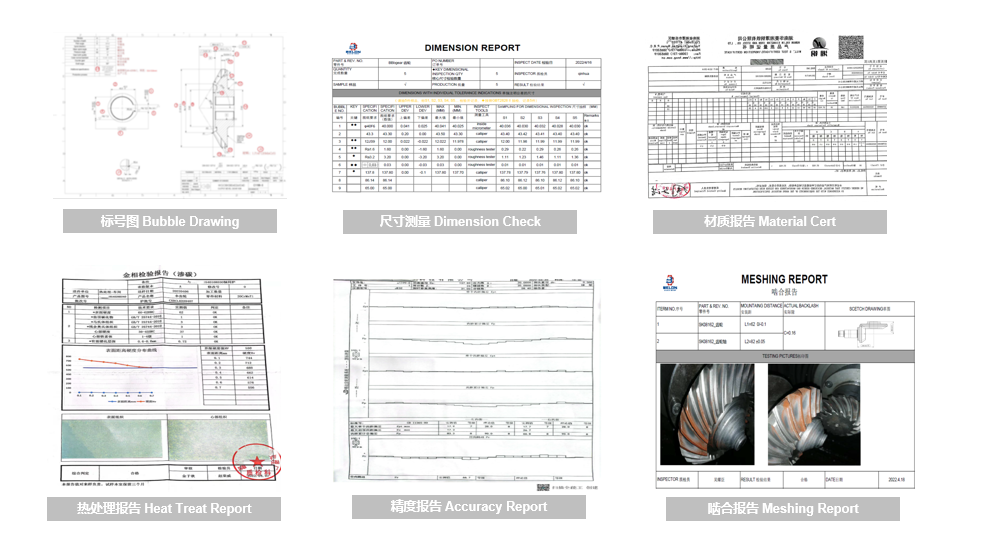

Cov Lus Qhia :, peb yuav muab cov lus qhia hauv qab no nrog rau cov duab thiab cov yeeb yaj kiab rau cov neeg siv khoom ua ntej txhua qhov kev xa khoom rau kev pom zoo rau lapping bevel iav.

1) npuas kos duab

2) Dimension daim ntawv qhia

3) Cov ntaub ntawv pov thawj

4) Daim ntawv qhia tseeb

5) Heat Treat report

6) Meshing report

Pem hauv ntej pob

Pem hauv ntej pob

Thawv

pob ntoo