Peb liBevel Iav Cov koog muaj nyob rau hauv cov ntau ntawm qhov ntau thiab tsawg thiab kev teeb tsa kom haum cov cuab yeej siv hnyav. Txawm hais tias koj xav tau ib chav ua ke ua ke chav ua ke rau tus ntses steer loader lossis chav tsev siab rau pob tseg rau koj cov kev xav tau. Peb kuj tseem muaj kev pabcuam tsim qauv thiab entrineering rau cov ntawv thov tshwj xeeb lossis kom paub meej tias koj tau txais lub ntsej muag zoo tshaj plaws rau koj cov cuab yeej hnyav.

Yuav muab cov ntawv tshaj tawm twg rau cov neeg siv khoom ua ntej xa khoom rau kev sib tsoo cov kauv loj bevel zog?

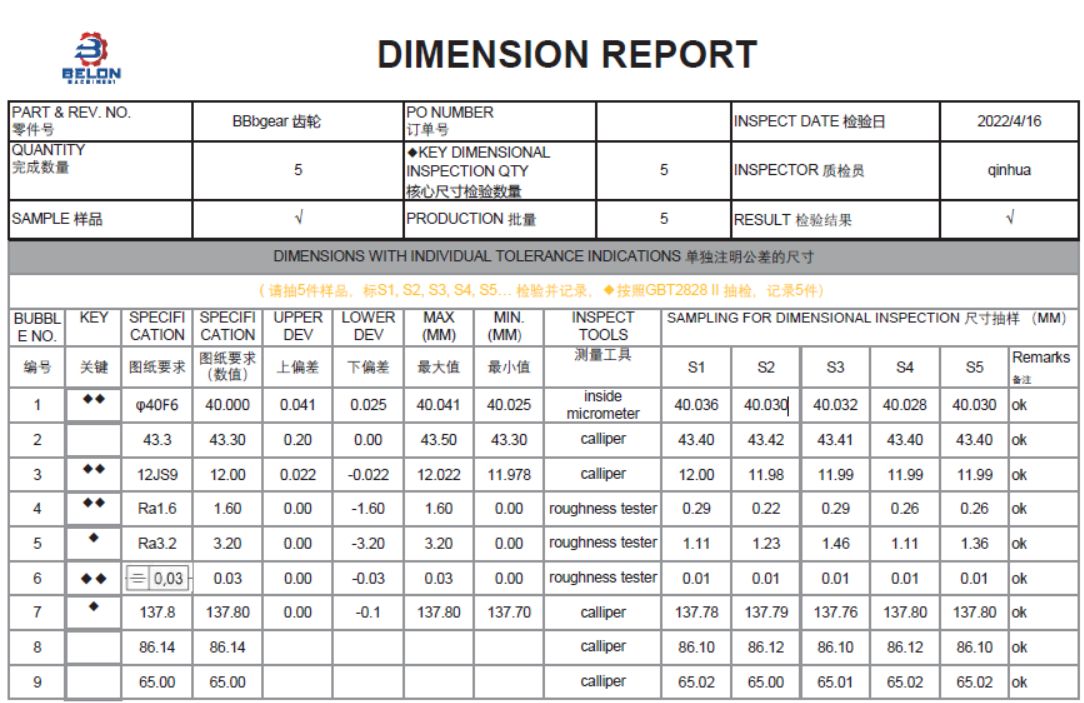

1) npuas kos duab

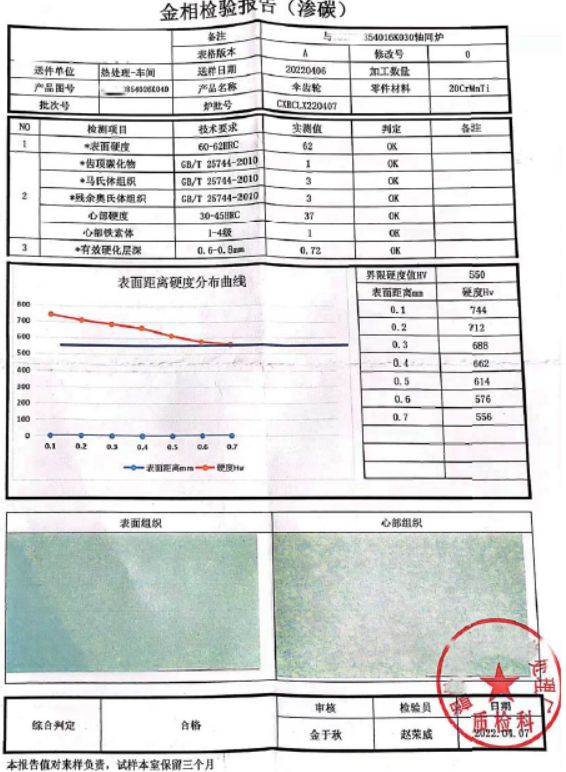

2) Daim Ntawv Qhia Tawm Tsam

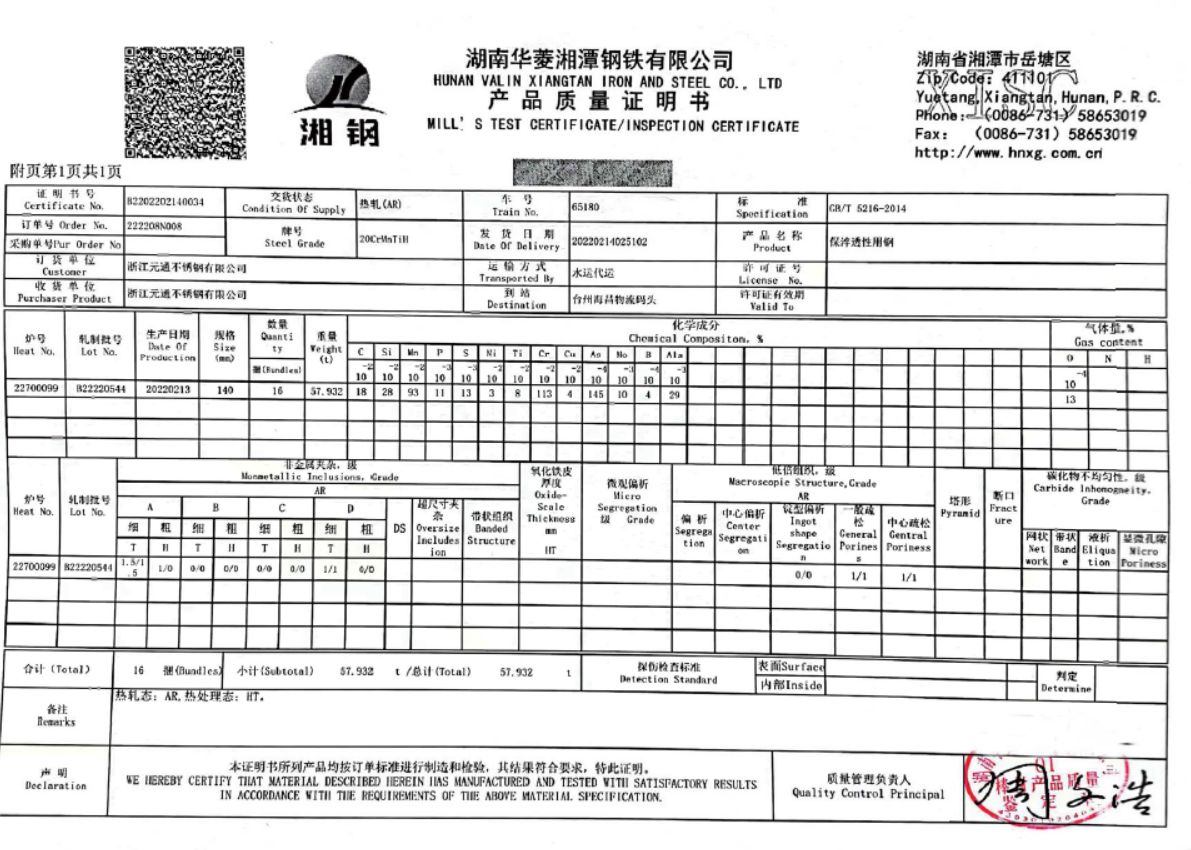

3) Cov Khoom Sau Ntawv

4) Daim Ntawv Kho Mob Sov

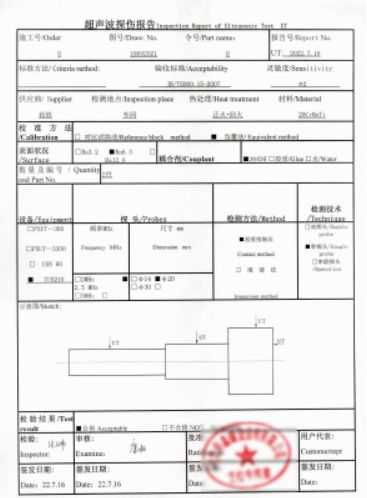

5) Daim ntawv qhia xeem ntawv ultrasonic (ut)

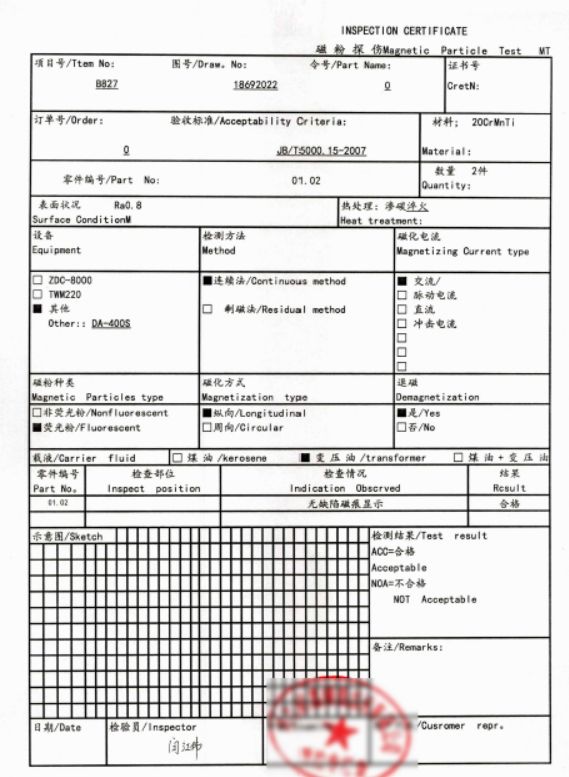

6) Sib Nqus Particle Particle Ntsuas Daim Ntawv Tshaj Tawm (MT)

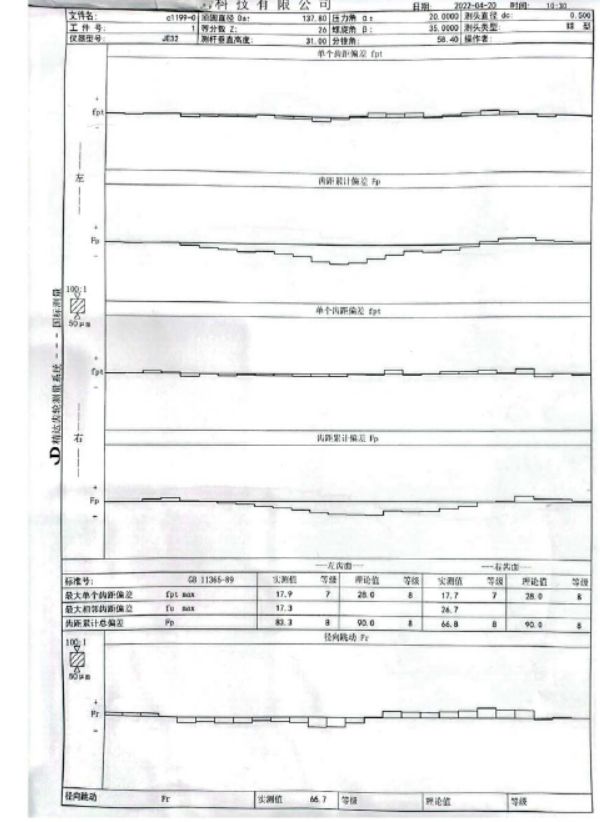

Daim Ntawv Qhia Txog Meshing Xeem Ntawv

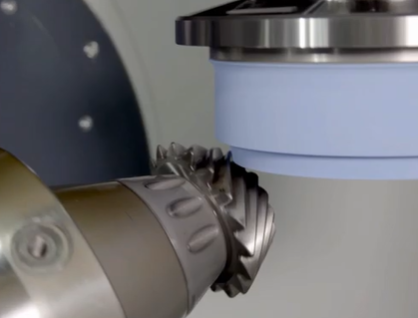

Peb sib tham thaj tsam ntawm 200000 square metres, kuj tseem nruab nrog cov khoom siv ntau lawm thiab tshuaj xyuas cov khoom siv kom tau raws li cov neeg siv khoom xav tau. Peb tau qhia qhov loj tshaj plaws, Suav thawj cov iav fest16000 tsib-axis machisent center vim kev koom tes ntawm gleason thiab holler.

→ Txhua yam

Txhua tus lej ntawm cov hniav

Siab Tshaj Lij Tshaj Lij

High efficiency, siab precision

Nqa cov kev npau suav tsim kev tsim khoom, yooj thiab kev lag luam rau cov pob me me.

Cov khoom siv raw

kev txiav

txoj siav

quenching thiab tempering

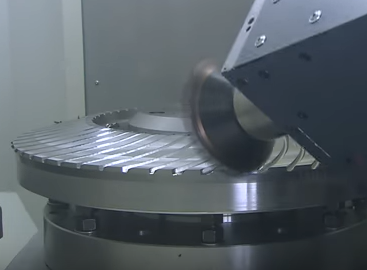

Iav milling

Cua Sov Kho

Iav milling

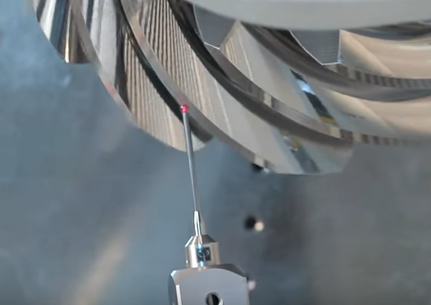

kev kuaj