Lapped bevel gears yog cov bevel gear hom siv feem ntau hauv gearmotors thiab reducers. Qhov sib txawv piv nrog cov av bevel gears, ob qho tib si muaj lawv qhov zoo thiab qhov tsis zoo.

Cov iav av bevel zoo:

1. Qhov roughness ntawm cov hniav yog qhov zoo. Los ntawm kev sib tsoo cov hniav tom qab cua sov, qhov roughness ntawm cov khoom tiav tuaj yeem lav tau tias yuav siab dua 0.

2. Qib siab precision. Cov txheej txheem sib tsoo iav yog feem ntau yog kho qhov deformation ntawm lub iav thaum lub sijhawm kho cua sov, kom ntseeg tau tias qhov tseeb ntawm lub iav tom qab ua tiav, tsis muaj kev co thaum lub sijhawm ua haujlwm ceev (saum toj no 10,000 rpm), thiab kom ua tiav lub hom phiaj ntawm kev tswj hwm qhov tseeb ntawm lub iav kis;

Cov iav av bevel tsis zoo:

1. Tus nqi siab. Kev sib tsoo iav xav tau ntau lub tshuab, thiab tus nqi ntawm txhua lub tshuab sib tsoo iav yog ntau dua 10 lab yuan. Cov txheej txheem tsim khoom kuj kim heev. Muaj lub chaw ua haujlwm kub tas li. Tus nqi ntawm lub log sib tsoo yog ntau txhiab, thiab muaj cov lim dej, thiab lwm yam, yog li kev sib tsoo kim dua, thiab tus nqi ntawm txhua pawg yog li 600 yuan;

2. Kev ua haujlwm tsawg thiab txwv los ntawm lub kaw lus iav. Kev sib tsoo iav bevel yog ua tiav ntawm ntau lub tshuab cuab yeej, thiab lub sijhawm sib tsoo yog tsawg kawg 30 feeb. Thiab tsis tuaj yeem sib tsoo cov hniav;

3. Txo qhov ua tau zoo ntawm cov khoom. Hais txog kev ua tau zoo ntawm cov khoom, cov txheej txheem sib tsoo iav tshem tawm cov txheej zoo tshaj plaws ntawm qhov tawv tawv ntawm qhov chaw iav tom qab kev kho cua sov, thiab nws yog cov txheej tawv no uas txiav txim siab lub neej ua haujlwm ntawm cov iav. Yog li ntawd, cov tebchaws tsim kho xws li Nyiv tsis sib tsoo cov iav bevel rau tsheb kiag li.

Cov txiaj ntsig thiab qhov tsis zoo ntawm Lapped bevel gears

1. Ua haujlwm tau zoo. Tsuas yog siv sijhawm li 5 feeb los sib tsoo ib khub iav, uas tsim nyog rau kev tsim khoom loj.

2. Qhov cuam tshuam txo suab nrov zoo. Cov hniav sib tsoo raug ua tiav ua khub, thiab kev sib txuas ntawm cov hniav nto zoo. Qhov chaw nkag los daws qhov teeb meem suab nrov heev thiab qhov cuam tshuam txo suab nrov yog li 3 decibels qis dua li ntawm cov hniav sib tsoo.

3. Tus nqi qis. Kev txhuam iav tsuas yog yuav tsum tau ua rau ntawm ib lub cuab yeej tshuab, thiab tus nqi ntawm lub cuab yeej tshuab nws tus kheej kuj qis dua li ntawm lub tshuab sib tsoo iav. Cov ntaub ntawv pabcuam siv kuj qis dua li cov uas xav tau rau kev sib tsoo hniav

4. Tsis txwv los ntawm cov qauv hniav. Vim tias cov hniav tsis tuaj yeem sib tsoo tau, tom qab xyoo 1995, Olycon tau tsim cov thev naus laus zis sib tsoo, uas tsis tsuas yog tuaj yeem ua cov hniav uas muaj qhov siab sib npaug xwb, tab sis kuj tuaj yeem ua cov hniav uas me dua. Thiab cov txheej txheem no tsis tau rhuav tshem cov txheej saum npoo uas tau kho kom sov.

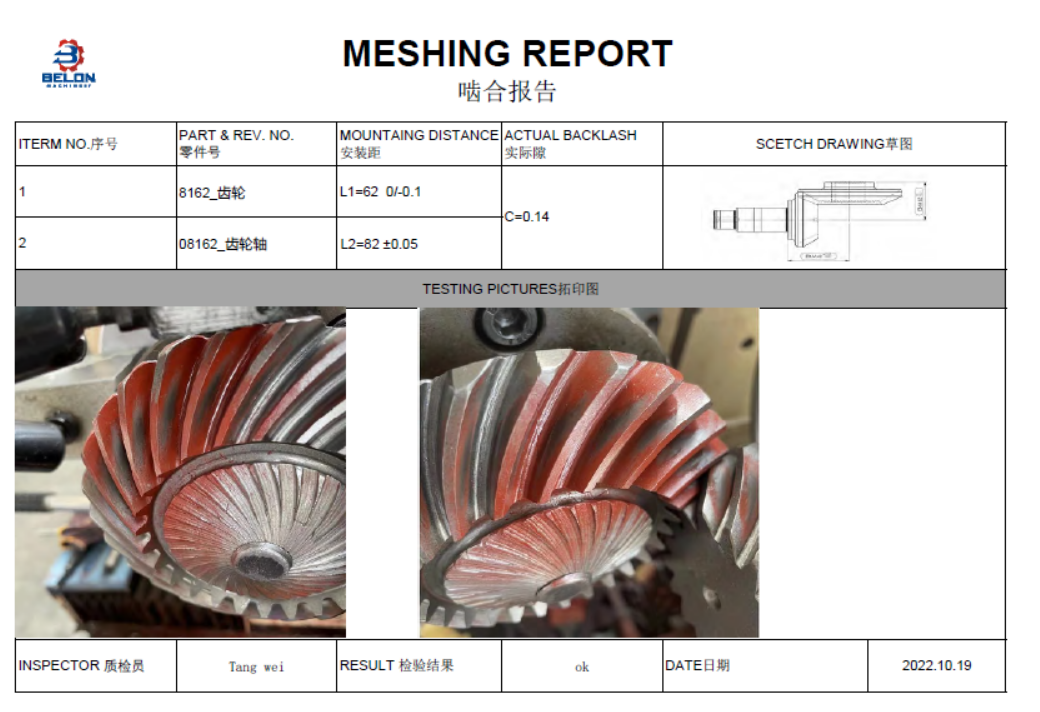

Yog tias koj tab tom yuav koj cov iav lapped bevel, hom ntawv ceeb toom twg koj yuav tsum tau txais los ntawm koj tus neeg muag khoom? Hauv qab no yog peb li uas yuav raug qhia rau cov neeg siv khoom ua ntej txhua qhov kev xa khoom.

1. Kev kos duab npuas: peb tau kos npe rau NDA nrog txhua tus neeg siv khoom, yog li peb ua kom daim duab tsis meej

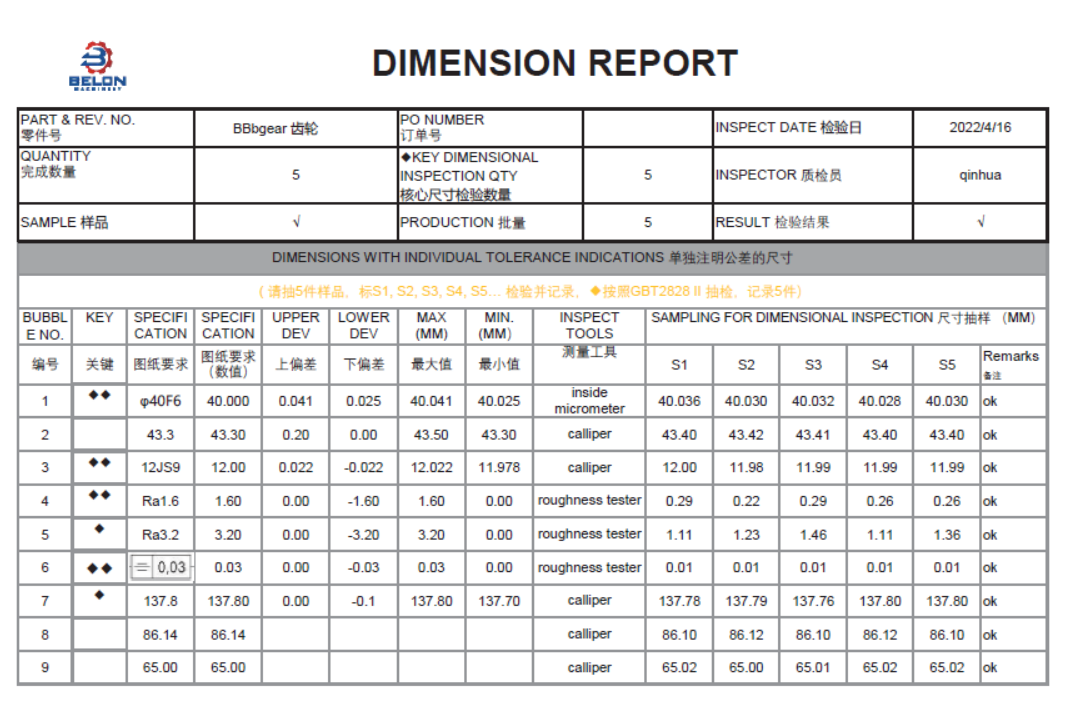

2. Daim Ntawv Qhia Txog Qhov Loj Tseem Ceeb

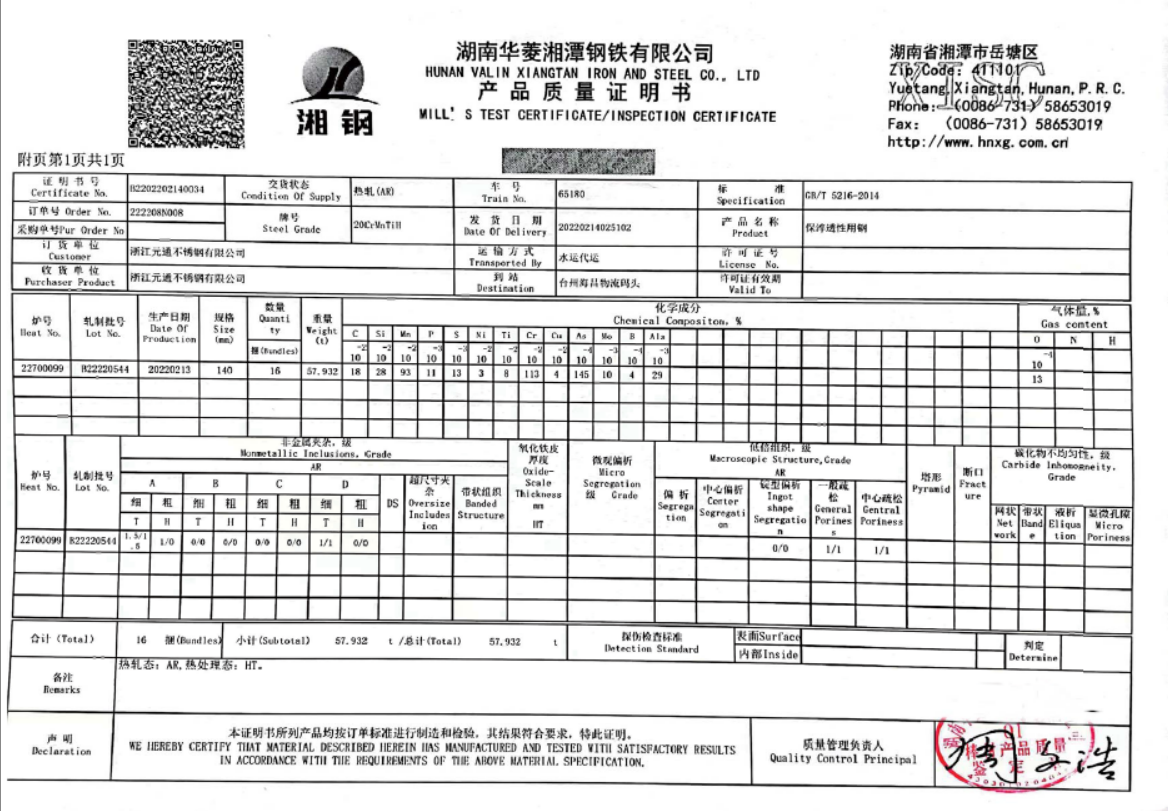

3. Daim Ntawv Pov Thawj Khoom Siv

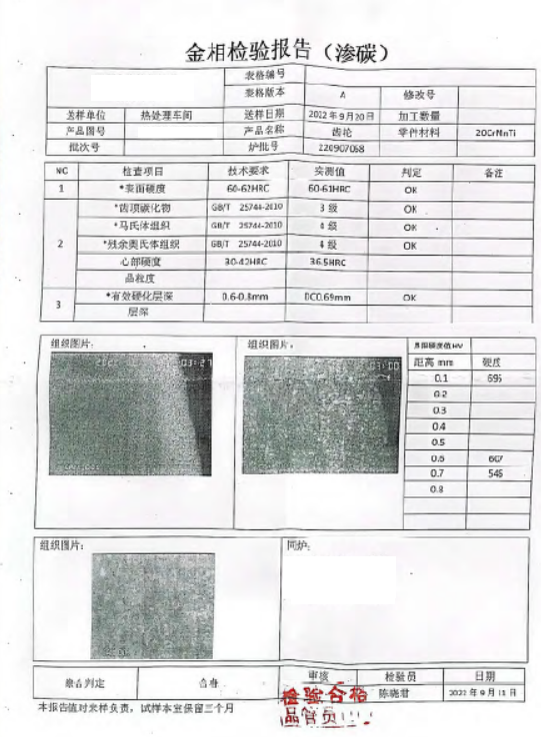

4. Daim Ntawv Qhia Txog Kev Kho Mob Kub

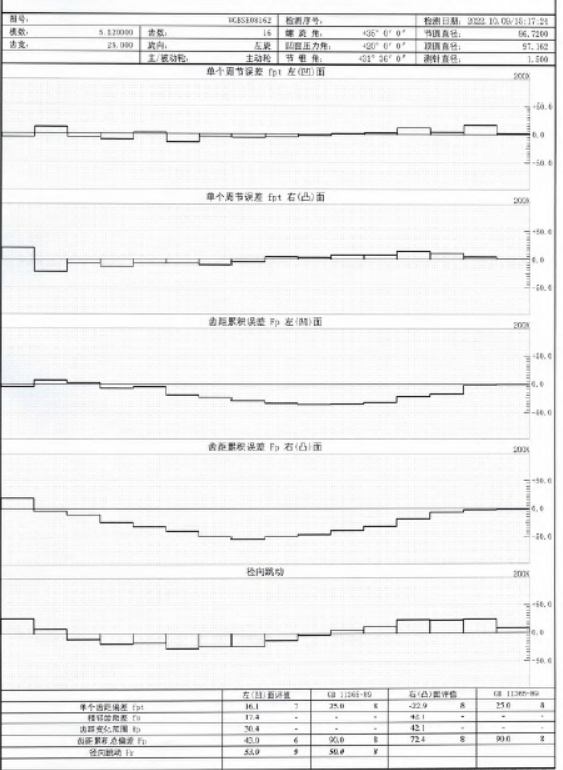

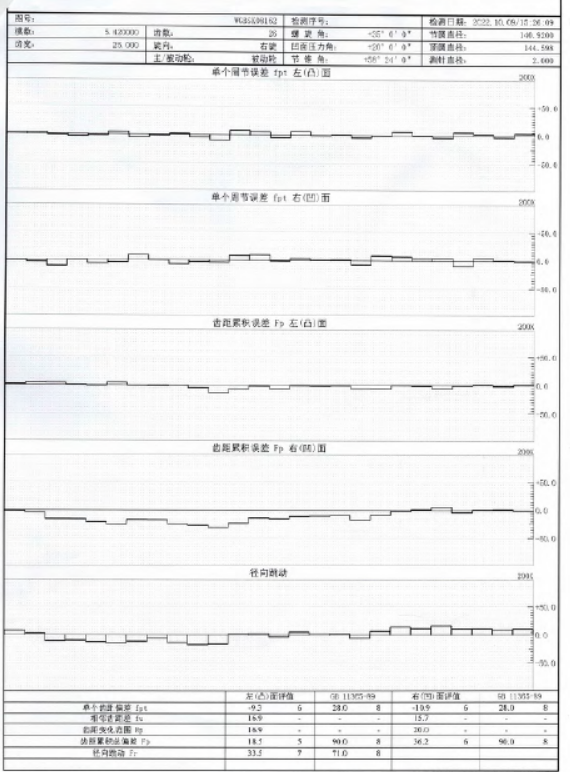

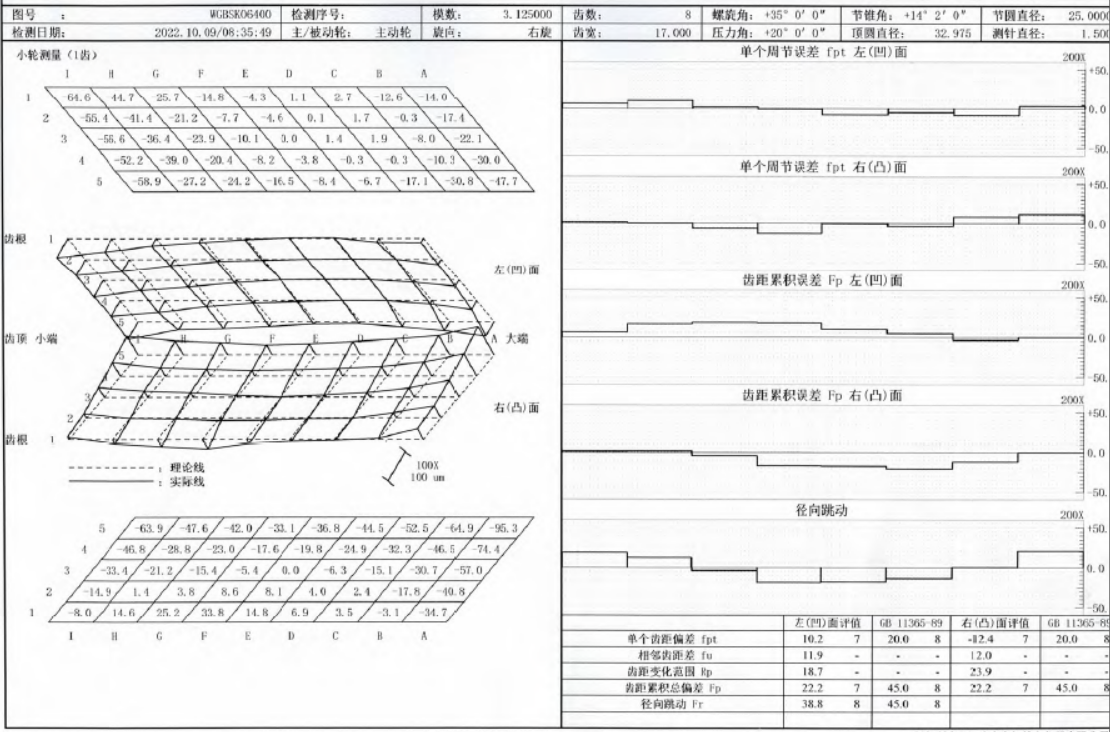

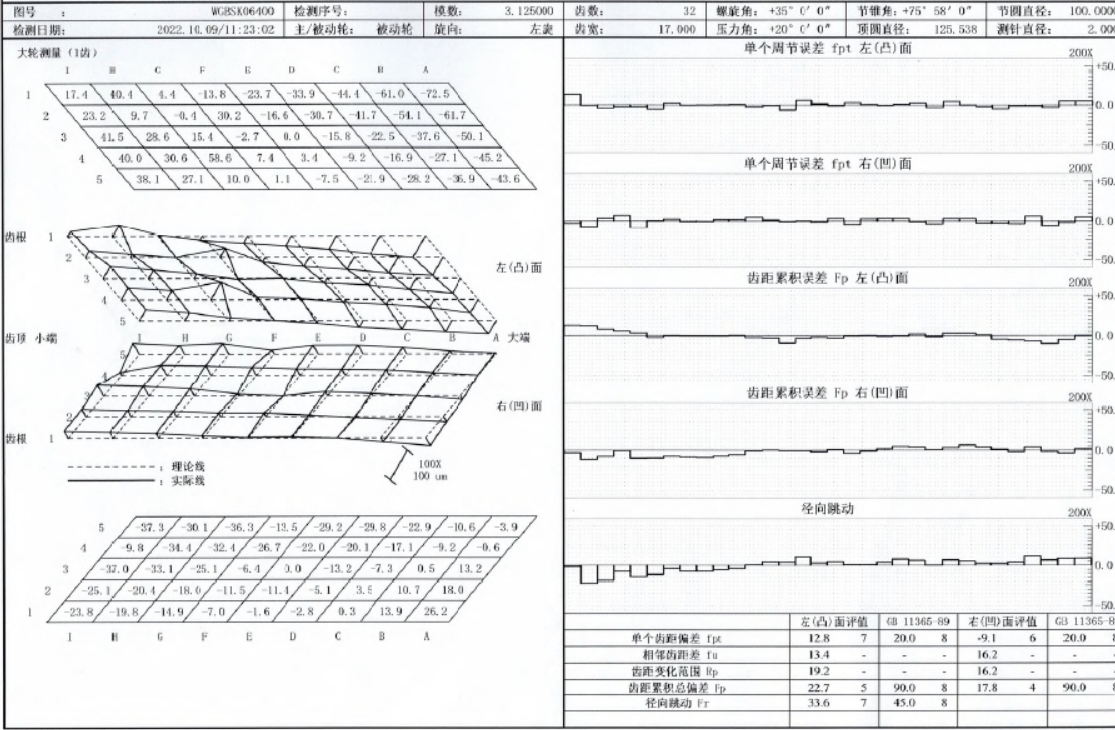

5. Daim Ntawv Qhia Txog Qhov Tseeb

6. Daim Ntawv Qhia Txog Kev Sib Tham

Nrog rau qee cov yeeb yaj kiab kuaj uas koj tuaj yeem tshawb xyuas ntawm qhov txuas hauv qab no

kev sim meshing rau lapping bevel iav - qhov deb ntawm qhov chaw thiab kev sim backlash

https://youtube.com/shorts/5cMDyHXMvf0

kev ntsuam xyuas qhov khiav tawm ntawm qhov chaw | rau qhov chaw ntawm cov iav bevel

https://youtube.com/shorts/Y1tFqBVWkow

Lub sijhawm tshaj tawm: Kaum Ib Hlis-03-2022