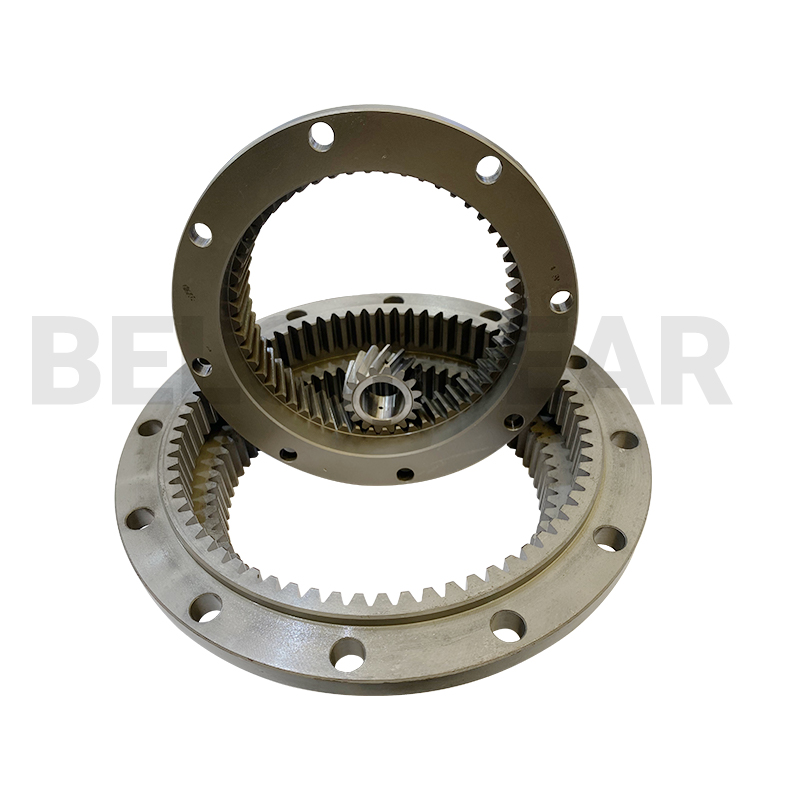

Cov iav sab hauvyog ib hom iav uas cov hniav raug txiav rau sab hauv ntawm lub tog raj kheej lossis lub khob hliav qab, piv rau cov iav sab nraud uas cov hniav nyob rau sab nraud. Lawv sib txuas nrog cov iav sab nraud, thiab lawv tus qauv tsim ua rau lawv xa cov kev txav mus los thiab lub zog hauv ntau yam tshuab.

Muaj ntau daim ntawv thov rau cov iav sab hauv:

- Cov Txheej Txheem Gear Planetary: Cov iav sab hauv feem ntau siv rau hauv cov txheej txheem iav planetary, qhov chaw uas lawv sib txuas nrog lub hnub iav thiab lub ntiaj teb iav. Qhov kev npaj no tso cai rau cov tsheb iav me me thiab ntau yam, feem ntau siv rau hauv kev sib kis tsheb thiab cov tshuab kev lag luam.

- Kev Xa Hluav Taws Xob: Cov iav sab hauv tuaj yeem siv los xa hluav taws xob ntawm cov ncej sib luag lossis sib tshuam. Lawv feem ntau siv rau hauv cov xwm txheej uas qhov chaw txwv lossis qhov xav tau torque tshwj xeeb xav tau lawv siv.

- Txo lossis Nce Kev Ceev: Cov iav sab hauvsiv tau los ua kom nce lossis txo qhov ceev ntawm kev sib hloov nyob ntawm lawv qhov kev teeb tsa thiab kev sib txuas nrog cov iav sab nraud.

- Kev Tswj Xyuas Kev Txav Mus Los: Hauv kev siv tshuab robotics thiab automation, cov iav sab hauv yog siv rau kev tswj kev txav mus los kom meej, kom ntseeg tau tias kev txav mus los du thiab raug hauv cov caj npab robotic, CNC tshuab, thiab lwm yam tshuab tsis siv neeg.

- Cov Txheej Txheem Sib Txawv: Cov iav sab hauv kuj tseem tuaj yeem pom muaj nyob rau hauv cov txheej txheem sib txawv, xws li cov uas siv hauv cov tsheb tsav tsheb, los faib lub zog thiab lub zog ntawm cov log thaum tso cai rau lawv tig ntawm ntau qhov ceev.

- In kev siv neeg hlau thiab kev ua haujlwm tsis siv neeg, cov iav sab hauv yog siv dav kom ua tiav kev txav mus los meej hauv qhov chaw tsawg. Piv txwv li, cov caj npab neeg hlau feem ntau siv cov iav sab hauv hauv lawv cov actuators los muab qhov chaw raug nrog qhov rov qab tsawg kawg nkaus, ua rau kev txav mus los du thiab tswj tau zoo dua. Qhov xwm txheej me me ntawm cov iav sab hauv pab cov engineers sib koom ua ke cov iav nyuaj hauv cov rooj sib dhos me me, tso cai rau cov neeg hlau kom tswj tau qib siab ntawm kev ywj pheej thiab kev ua haujlwm zoo yam tsis muaj kev txi lub zog lossis kev tswj hwm.

- Cov iav sab hauv kuj yog ib qho kev xaiv nrov hauvcov tsheb fais fab (EVs), tshwj xeeb tshaj yog nyob rau hauv cov gearboxes tsim los tswj cov kev sib hloov ceev siab. EV motors feem ntau ua haujlwm ntawm qhov ceev siab dua li cov cav combustion sab hauv, yog li cov iav sab hauv, ua ke nrog cov planetary gear systems, yog qhov tseem ceeb rau kev txo qhov ceev thaum ua kom lub zog loj dua. Qhov kev teeb tsa no ua rau kev siv hluav taws xob zoo dua, ua rau kev xa hluav taws xob du thiab lub roj teeb ntev dua.

- In cov tshuab luam ntawvthiabcov tshuab textile, qhov twg qhov kev ua haujlwm siab yog qhov tseem ceeb, cov iav sab hauv yog siv rau hauv cov kab ke uas xav tau kev sib hloov thiab kev ceev sib dhos. Kev teeb tsa iav sab hauv pab ua kom muaj kev sib xws thiab kev ua haujlwm raug, pab txhawb rau qhov zoo ntawm cov khoom kawg, txawm tias nws yog cov ntaub ntawv luam tawm lossis cov ntaub. Lawv cov qauv me me thiab kev sib koom ua haujlwm tau zoo ua rau cov tshuab no ua haujlwm ntawm qhov ceev siab yam tsis muaj kev pheej hmoo ntawm kev tsis sib haum xeeb lossis kev hnav ntau dhau.

Tsis tas li ntawd xwb,cov khoom siv kho mobzoo li cov neeg hlau phais thiab cov tshuab thaij duab feem ntau siv cov iav sab hauv hauv lawv cov actuators rau kev txav mus los kom raug, tswj tau hauv qhov chaw me me. Cov iav sab hauv pab tswj qhov tseeb thiab ruaj khov, uas yog qhov tseem ceeb rau kev ua haujlwm zoo, kev kuaj mob, thiab kev nyab xeeb ntawm tus neeg mob.

Kev tsim thiab tsim cov iav sab hauv tuaj yeem nyuaj dua li cov iav sab nraud vim tias nyuaj rau nkag mus rau sab hauv ntawm lub iav thaum lub sijhawm ua haujlwm. Txawm li cas los xij, lawv muaj cov txiaj ntsig hauv qee qhov kev siv, xws li kev sib dhos me me, lub peev xwm kis tau torque ntau dua, thiab kev ua haujlwm du dua.

Lub sijhawm tshaj tawm: Plaub Hlis-30-2024