Cov khoom siv tshebkev sib kis tau dav dav, thiab nws paub dav ntawm cov neeg uas muaj kev nkag siab yooj yim txog lub tsheb. Piv txwv li suav nrog lub tsheb lub kis tau, lub qag tsav, qhov sib txawv, lub kauj tsheb, thiab txawm tias qee qhov khoom siv hluav taws xob xws li lub qhov rais fais fab, lub wiper, thiab lub tes nres hluav taws xob. Vim tias cov iav tau siv dav thiab ua lub luag haujlwm tseem ceeb hauv tsheb, hnub no peb yuav tham txog kev paub txog cov iav hauv tsheb.

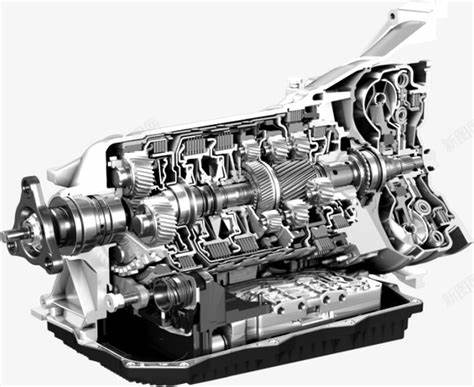

Kev sib kis iav yog ib qho ntawm cov kev sib kis siv dav hauv tsheb thiab muaj cov haujlwm tseem ceeb hauv qab no:

1. Kev hloov ceev: Los ntawm kev sib txuas ob lub iav sib txawv, qhov ceev ntawm lub iav tuaj yeem hloov pauv. Piv txwv li, cov iav hauv lub kis tau tuaj yeem txo lossis nce qhov ceev uas xa los ntawm lub cav kom tau raws li qhov xav tau ntawm lub tsheb ua haujlwm.

2. Kev hloov pauv ntawm lub zog: Thaum sib txuas ob lub iav ntawm qhov sib txawv, qhov ceev thiab lub zog torque uas xa los ntawm lub iav kuj raug hloov pauv. Piv txwv li suav nrog lub reducer tseem ceeb hauv lub qag tsav thiab lub tsheb kis.

3. Kev hloov pauv kev taw qhia: Lub zog ntawm lub cav ntawm qee lub tsheb yog perpendicular rau kev taw qhia ntawm lub tsheb txav mus los, yog li nws yog qhov tsim nyog los hloov kev taw qhia ntawm lub zog kis tau los tsav lub tsheb. Lub cuab yeej no feem ntau yog lub ntsiab reducer thiab differential hauv lub tsheb.

Hauv cov tsheb, qee qhov chaw siv cov iav ncaj, thaum lwm tus siv cov iav helical. Cov iav ncaj muaj kev sib kis zoo vim tias cov hniav sib koom thiab sib cais tag nrho cov hniav dav tib lub sijhawm. Txawm li cas los xij, qhov tsis zoo yog kev ruaj khov tsis zoo, kev cuam tshuam, thiab suab nrov siab. Ntawm qhov tod tes, cov iav helical muaj cov txheej txheem sib koom hniav ntev dua thiab ntau cov hniav koom nrog kev sib koom tes piv rau cov iav ncaj, ua rau muaj kev sib kis du, muaj peev xwm thauj khoom hnyav, thiab suab nrov thiab kev cuam tshuam tsawg. Qhov tsis zoo tseem ceeb ntawm cov iav helical yog tias lawv tsim cov zog axial thaum raug rau cov zog ib txwm muaj, xav tau cov kabmob thawb kom ntsia, ua rau muaj cov qauv nyuaj dua.

Cov kev cai raucov iav tshebyog siab, lub cev iav yuav tsum muaj kev tiv thaiv siab rau kev tawg, qhov chaw hniav yuav tsum muaj kev tiv thaiv zoo rau kev xeb, hnav thiab muaj peev xwm sib txuas siab, uas yog, nws xav kom qhov chaw hniav tawv thiab lub hauv paus tawv. Yog li ntawd, cov txheej txheem ua cov iav tsheb kuj nyuaj, nrog rau cov txheej txheem hauv qab no:

Txiav ➟ Forging ➟ Annealing ➟ Machining ➟ Ib Feem Tooj Liab Plating ➟ Carburizing ➟ Quenching ➟ Tempering Kub Qis ➟ Shot Peening ➟ Sib Tsoo Hniav (Sib Tsoo Zoo)

Txoj kev ua cov iav no tsis yog tsuas yog muaj lub zog thiab kev tawv txaus xwb, tab sis kuj muaj qhov nyuaj thiab hnav tsis kam ntawm cov hniav.

Lub sijhawm tshaj tawm: Lub Ob Hlis-09-2023