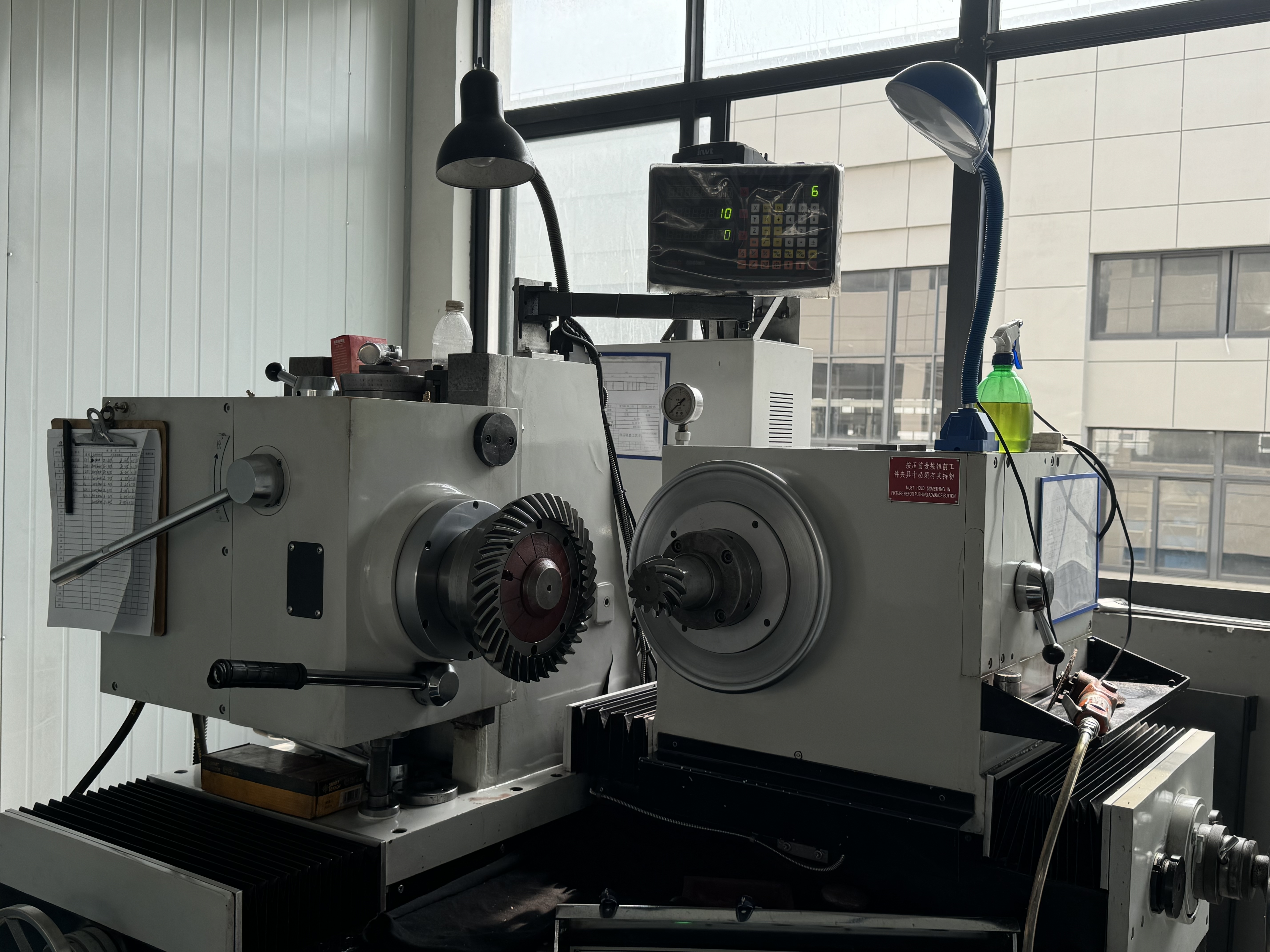

Cov txheej txheem iav ua lub luag haujlwm tseem ceeb hauv ntau yam khoom siv kho tshuab, ua kom muaj kev sib kis zoo thiab ua haujlwm tau zoo. Txawm li cas los xij, kev ua tau zoo ntawm cov txheej txheem iav vam khom rau qhov tseeb ntawmkev sib txuas iavTxawm tias qhov kev hloov me me tuaj yeem ua rau tsis muaj txiaj ntsig, kev hnav thiab tsim kua muag ntau ntxiv, thiab txawm tias muaj kev puas tsuaj loj heev. Hauv tsab xov xwm no, peb yuav tshawb nrhiav txog cov yam uas cuam tshuam rau qhov tseeb ntawm cov iav mesh thiab tshawb nrhiav lawv qhov tseem ceeb hauv kev ua kom muaj kev ua haujlwm zoo tshaj plaws ntawm lub iav.

Cov Hniav Iav Profile:

Qhov profile ntawm cov hniav iav tej zaum yog qhov tseem ceeb tshaj plaws uas cuam tshuam rau qhov tseeb ntawm cov iav mesh. Cov hniav yuav tsum tau ua kom raug kom ntseeg tau tias muaj kev sib koom tes zoo thiab tsawg kawg nkaus backlash. Txhua qhov kev hloov pauv ntawm qhov profile hniav zoo tagnrho tuaj yeem ua rau muaj kev thauj khoom tsis sib xws, suab nrov ntxiv, thiab txo qis kev ua haujlwm. Cov txheej txheem tsim khoom niaj hnub xws li CNC machining tau txhim kho lub peev xwm los tsim cov profile hniav iav kom raug.

Kev Tsim Khoom Siv Tau:

Cov txheej txheem tsim khoom yeej ib txwm ua rau muaj kev kam rau siab, uas tuaj yeem cuam tshuam rau qhov tseeb ntawm cov iav mesh. Kev hloov pauv ntawm qhov loj me, qhov tiav ntawm qhov chaw, thiab cov khoom siv tuaj yeem cuam tshuam rau qhov kev sib cuam tshuam ntawm cov iav thaum lub sijhawm sib txuas. Kev kam rau siab dua thiab kev tswj xyuas zoo thaum lub sijhawm tsim khoom yog qhov tseem ceeb rau kev ua kom cov iav ua haujlwm zoo ib yam.

Kev Sib Tov thiab Kev Sib Dhos:

Kev sib dhos thiab kev teeb tsa kom raugiavcov txheej txheem yog qhov tseem ceeb rau kev ua tiav qhov tseeb ntawm cov mesh. Kev tsis sib haum ntawm cov shafts, qhov sib nrug tsis raug ntawm cov iav, lossis kev thauj khoom tsis raug tuaj yeem ua rau kev thauj khoom tsis sib xws thiab hnav ua ntej. Kev ua tib zoo saib xyuas cov txheej txheem sib dhos, suav nrog kev siv cov cuab yeej sib dhos thiab cov lus qhia torque, yog qhov tsim nyog los txo cov teeb meem no.

Kev Siv Lubrication:

Kev siv roj nplua nyeem zoo yog qhov tseem ceeb rau kev txo qhov kev sib txhuam thiab kev hnav ntawm cov hniav iav. Kev tsis siv roj nplua nyeem txaus lossis tsis raug tuaj yeem ua rau muaj kev sib txhuam ntau ntxiv, kub dhau, thiab hnav sai dua. Kev xaiv cov roj nplua nyeem zoo, nrog rau kev saib xyuas thiab saib xyuas cov qib roj nplua nyeem tas li, yog qhov tseem ceeb rau kev tswj hwm qhov tseeb ntawm cov iav mesh dhau sijhawm.

Kev Ua Haujlwm:

Qhov chaw ua haujlwm kuj tseem tuaj yeem cuam tshuam rau qhov tseeb ntawm cov iav mesh. Cov yam xws li qhov kub thiab txias hloov pauv, kev poob siab, thiab kev ua qias tuaj yeem cuam tshuam rau kev ua haujlwm ntawm cov iav.iavcov kab ke uas muaj kev tiv thaiv tsim nyog thiab xav txog cov xwm txheej ua haujlwm uas tau npaj tseg tuaj yeem pab txo cov teebmeem no thiab xyuas kom meej tias muaj kev ua haujlwm zoo.

Kev Hnav thiab Kev Poob Qis:

Raws li lub sijhawm dhau mus, cov iav yuav raug kev hnav thiab puas tsuaj, cuam tshuam rau lawv qhov tseeb ntawm cov mesh. Cov khoom me me uas ua rau puas tsuaj, tsis muaj roj nplua nyeem txaus, lossis cov khoom thauj ntau dhau tuaj yeem ua rau kev hnav sai dua thiab ua rau muaj kev hloov pauv hauv cov qauv iav. Kev tshuaj xyuas thiab kev saib xyuas tsis tu ncua yog qhov tseem ceeb rau kev kuaj pom thiab daws cov teeb meem hnav ua ntej lawv ua rau kev ua haujlwm ntawm iav puas tsuaj.

Ua tiav thiab tswj hwmiavQhov tseeb ntawm cov mesh yog qhov tseem ceeb rau kev ua haujlwm ntawm cov txheej txheem kho tshuab kom ntseeg tau thiab ua haujlwm tau zoo. Los ntawm kev nkag siab txog cov yam ntxwv uas cuam tshuam rau qhov tseeb ntawm cov iav mesh thiab kev siv cov kev ntsuas tsim nyog thaum tsim qauv, tsim khoom, sib dhos, thiab ua haujlwm, cov engineers tuaj yeem ua kom zoo dua qhov kev ua haujlwm ntawm cov iav thiab txuas ntxiv lub neej ntawm cov txheej txheem iav. Kev nce qib tas mus li hauv cov thev naus laus zis tsim khoom thiab cov ntaub ntawv, ua ke nrog kev coj ua zoo, yuav txuas ntxiv txhim kho qhov tseeb ntawm cov iav mesh thiab tsav kev tsim kho tshiab hauv kev tsim kho tshuab.

Lub sijhawm tshaj tawm: Tsib Hlis-07-2024