Cov iav hmoov metallurgy

Hmoov metallurgy yog ib txoj kev tsim khoom uas muaj kev sib xyaw cov hmoov hlau hauv qab siab thiab tom qab ntawd sintering lawv ntawm qhov kub siab kom tsim cov khoom khov.

Hmoov hlaucov iavyog siv dav hauv ntau yam lag luam xws li tsheb, khoom siv kev lag luam thiab kev siv hluav taws xob.

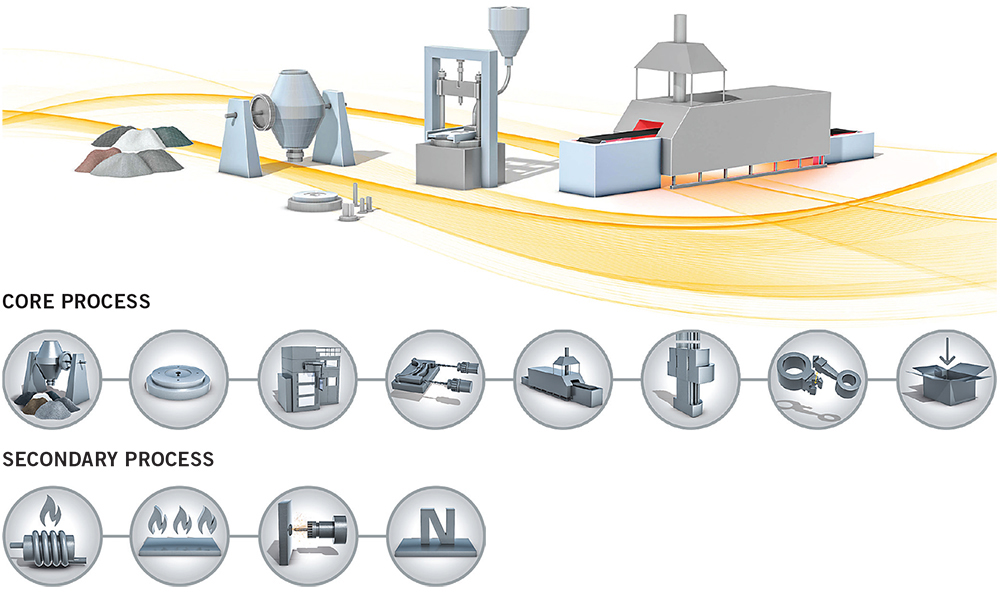

Cov txheej txheem tseem ceeb ntawm cov hmoov metallurgy suav nrog kev sib tov hmoov, kev siv cuab yeej, kev nias hmoov, kev siv tshuab ntsuab, sintering, kev ntsuas qhov loj, kev ntim khoom thiab kev tshuaj xyuas zaum kawg. Cov haujlwm thib ob suav nrog kev ua kom tawv tawv, kev siv tshuab kho cua sov thiab nitriding.

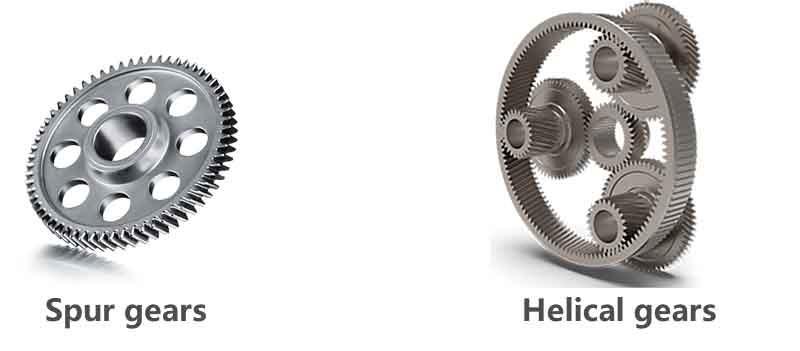

Cov iav hlau hmoov, zoo li cov iav uas tsim los ntawm lwm cov txheej txheem tsim khoom, tuaj yeem ua tiav rau hauv ntau yam duab hniav raws li qhov xav tau. Qee cov duab hniav uas siv rau cov iav hlau hmoov suav nrog:cov iav spur, cov iav helical.

Cov khoom siv hlau hmoov:

Thaum xaiv cov ntaub ntawv rau cov iav hmoov metallurgy, ntau yam yuav tsum tau xav txog: cov khoom siv kho tshuab, qhov ceev, lubrication thiab hnav, tus nqi

Cov teb thov:

Cov iav hmoov hlau siv rau hauv ntau yam kev siv tshuab hauv tsheb, suav nrog:

1. Lub thawv iav: Cov iav hmoov hlau siv dav hauv cov thawv iav tsis siv neeg thiab phau ntawv kom muab kev sib kis hluav taws xob txhim khu kev qha thiab ua haujlwm tau zoo ntawm lub cav thiab lub log. Lawv lub zog siab thiab kev tiv thaiv kev hnav ua rau muaj kev hloov pauv du, txhim kho cov iav mesh thiab lub neej kis tau ntev.

2. Cov Tsheb Fais Fab: Raws li kev lag luam tshebkev hloov pauvRau cov tsheb fais fab (EVs), cov iav hlau hmoov ua lub luag haujlwm tseem ceeb hauv cov tshuab hluav taws xob. Cov iav no yog siv rau hauv cov tshuab hluav taws xob, cov gearboxes thiab cov differentials los muab cov torque thiab qhov ceev uas xav tau rau kev ua haujlwm zoo tshaj plaws ntawm EV.

3. Lub tshuab tsav: Lub tshuab tsav siv cov iav hlau hmoov los xa lub zog los ntawm lub kauj mus rau lub log. Lawv lub zog ruaj khov, kev ua haujlwm raug thiab kev ua haujlwm ntsiag to pab txhawb kev tswj hwm lub kauj uas teb tau zoo thiab raug.

Lub sijhawm tshaj tawm: Lub Yim Hli-28-2023