1. Tus naj npawb ntawm cov hniav Z Tus naj npawb tag nrho ntawm cov hniav ntawm ibiav.

2, modulus m Cov khoom ntawm qhov deb ntawm cov hniav thiab tus naj npawb ntawm cov hniav yog sib npaug rau qhov ncig ntawm lub voj voog faib, uas yog, pz = πd,

qhov twg z yog tus lej ntuj thiab π yog tus lej tsis muaj tseeb. Yuav kom d yog rational, qhov xwm txheej uas p/π yog rational hu ua modulus. Ntawd yog: m=p/π

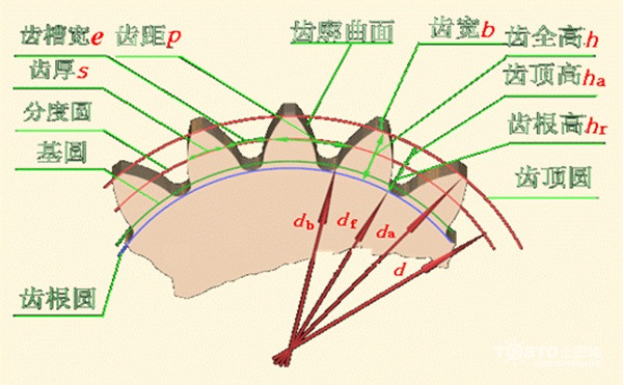

3, txoj kab uas hla ntawm lub voj voog indexing d qhov loj ntawm cov hniav ntawm lub iav raug txiav txim siab raws li lub voj voog no d = mz daim ntawv theej tag nrho 24, txoj kab uas hla ntawm lub voj voog sab saud d. Thiab txoj kab uas hla ntawm lub voj voog hauv paus de nyeem tag nrho cov vijtsam los ntawm cov mis xam ntawm qhov siab crest thiab qhov siab hauv paus, cov mis xam ntawm txoj kab uas hla lub voj voog crest thiab txoj kab uas hla lub voj voog hauv paus tuaj yeem tau los ntawm:

d.=d+2h.=mz+2m=m(z+2)

Qhov modulus ntawm lub log loj dua, qhov siab dua thiab tuab dua cov hniav, yog tias tus naj npawb ntawm cov hniav ntawm

iavyog qhov tseeb, qhov loj dua qhov loj ntawm lub log. Cov qauv modular series yog tsim raws li qhov yuav tsum tau ua ntawm kev tsim, kev tsim khoom thiab kev tshuaj xyuas. Rau cov iav uas muaj cov hniav tsis ncaj, cov modulus muaj qhov sib txawv ntawm cov modulus mn ib txwm, qhov kawg modulus ms thiab axial modulus mx, uas yog raws li qhov sib piv ntawm lawv cov suab (suab ib txwm, suab kawg thiab axial suab) rau PI, thiab kuj yog nyob rau hauv millimeters. Rau cov iav bevel, lub module muaj qhov kawg loj module me, qhov nruab nrab module mm thiab qhov kawg me module m1. Rau cov cuab yeej, muaj cov cuab yeej modulus mo sib xws thiab lwm yam. Cov qauv txheem tau siv dav. Hauv cov iav metric tsav, worm tsav, synchronous iav siv tsav thiab ratchet, iav coupling, spline thiab lwm yam khoom, cov qauv txheem modulus yog qhov yooj yim tshaj plaws. Nws ua lub luag haujlwm yooj yim parameter hauv kev tsim, kev tsim khoom thiab kev saib xyuas ntawm cov khoom saum toj no.

1) Lub modulus qhia txog qhov loj ntawm cov hniav. Lub R-module yog qhov sib piv ntawm lub suab ntawm lub voj voog faib rau PI (π), qhia hauv millimeters (mm). Ntxiv rau cov modules, peb muaj Diametral pitch (CP) thiab DP (Diametral pitch) los piav qhia txog qhov loj ntawm cov hniav. Lub diametral pitch yog qhov ntev ntawm lub arc faib ntawm cov ntsiab lus sib npaug ntawm ob lub hniav sib ze.

2) "Txoj kab uas hla ntawm lub voj voog ntsuas" yog dab tsi? Lub voj voog ntsuas yog txoj kab uas hla ntawmiavOb qho tseem ceeb uas txiav txim siab qhov loj ntawm lub iav yog modulus thiab tus lej ntawm cov hniav, thiab txoj kab uas hla ntawm lub voj voog faib yog sib npaug rau cov khoom ntawm tus lej ntawm cov hniav thiab modulus (qhov kawg ntawm lub ntsej muag).

3) "Lub kaum sab xis siab" yog dab tsi? Lub kaum sab xis ntse ntawm txoj kab radial ntawm qhov kev sib tshuam ntawm cov hniav thiab cov hniav tangent ntawm qhov taw tes hu ua Lub kaum sab xis siab ntawm lub voj voog siv. Feem ntau hais lus, lub kaum sab xis siab hais txog Lub kaum sab xis siab ntawm lub voj voog indexing. Lub kaum sab xis siab feem ntau siv yog 20 °; txawm li cas los xij, cov iav nrog lub kaum sab xis siab ntawm 14.5 °, 15 °, 17.5 °, thiab 22.5 ° kuj siv.

4) Qhov txawv ntawm cov kab laug sab ib lub taub hau thiab ob lub taub hau yog dab tsi? Tus naj npawb ntawm cov hniav sib dhos ntawm cov kab laug sab hu ua "tus naj npawb ntawm cov taub hau", uas yog sib npaug rau tus naj npawb ntawm cov hniav ntawm cov iav. Qhov ntau lub taub hau muaj, qhov loj dua lub kaum sab xis.

5) Yuav ua li cas thiaj paub qhov txawv ntawm R (sab xis)? L (sab laug) Lub iav ncej ntsug hauv av tiaj tiaj iav hniav qaij mus rau sab xis yog lub iav sab xis, qaij mus rau sab laug yog lub iav sab laug.

6) Qhov txawv ntawm M (modulus) thiab CP (pitch) yog dab tsi? CP (Circular pitch) yog lub voj voog ntawm cov hniav ntawm lub voj voog index. Lub unit zoo ib yam li modulus hauv millimeters. CP faib los ntawm PI (π) ua rau M (modulus). Kev sib raug zoo ntawm M (modulus) thiab CP yog qhia raws li nram no. M (modulus) =CP/π (PI) Ob qho tib si yog cov units ntawm qhov loj ntawm cov hniav. (Qhov faib circumference = nd=zpd=zp/ l/PI hu ua modulus)

7) "backlash" yog dab tsi? Qhov sib txawv ntawm cov hniav ntawm ob lub iav thaum lawv koom nrog. Backlash yog qhov tsim nyog rau kev ua haujlwm du ntawm kev sib txuas iav. 8) Qhov sib txawv ntawm lub zog khoov thiab lub zog ntawm cov hniav yog dab tsi? Feem ntau, lub zog ntawm cov iav yuav tsum tau xav txog los ntawm ob qho: khoov thiab lub zog ntawm cov hniav. Lub zog khoov yog lub zog ntawm cov hniav uas xa lub zog los tiv thaiv cov hniav tawg ntawm cov hauv paus vim yog qhov kev ua ntawm lub zog khoov. Lub zog ntawm cov hniav yog lub zog sib txhuam ntawm cov hniav thaum lub sijhawm sib cuag ntau zaus ntawm cov hniav sib txuas. 9) Hauv lub zog khoov thiab lub zog ntawm cov hniav, lub zog twg siv ua lub hauv paus rau kev xaiv cov iav? Feem ntau, ob qho tib si khoov thiab lub zog ntawm cov hniav yuav tsum tau tham txog. Txawm li cas los xij, thaum xaiv cov iav uas siv tsawg dua, cov iav tes, thiab cov iav meshing qeeb qeeb, muaj qee kis uas tsuas yog xaiv lub zog khoov. Thaum kawg, nws yog nyob ntawm tus tsim qauv los txiav txim siab.

Lub sijhawm tshaj tawm: Lub Kaum Hli-31-2024