Gleasoncov iav bevel spiralyog ib hom iav bevel tshwj xeeb uas tsim los xa lub zog ntawm cov ncej sib tshuam, feem ntau ntawm lub kaum sab xis 90 degree. Qhov ua rau Gleason system txawv yog nws cov hniav geometry thiab txoj kev tsim khoom tshwj xeeb, uas muab kev txav mus los du, muaj peev xwm siab torque, thiab ua haujlwm ntsiag to. Cov iav no siv dav hauv kev sib kis tsheb, kev lag luam, thiab aerospace qhov twg kev ntseeg tau thiab kev raug yog qhov tseem ceeb.

Lub Gleason system tau tsim los txhim kho qhov ncaj thiabZerol bevel iavlos ntawm kev qhia txog cov hniav uas nkhaus thiab zoo li lub kauv. Cov hniav uas zoo li lub kauv no ua rau maj mam sib koom ua ke ntawm cov hniav, txo cov suab nrov thiab kev co thaum tseem ua rau muaj kev sib hloov ceev dua thiab muaj peev xwm thauj khoom tau zoo dua. Tus qauv tsim kuj ua rau muaj kev sib cuag thiab lub zog ntawm qhov chaw, ua kom muaj kev xa hluav taws xob zoo thaum muaj cov khoom hnyav lossis cov khoom hnyav.

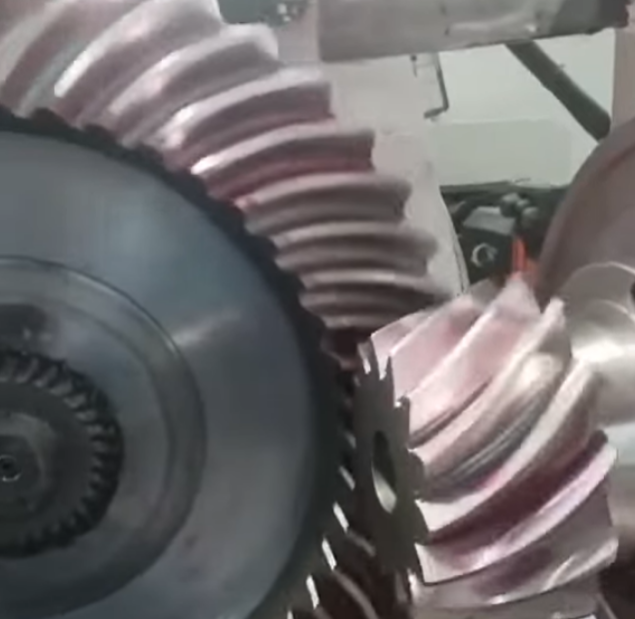

Txhua khub iav Gleason spiral bevel muaj ib lub pinion thiab ib lub iav mating, tsim nrog cov geometry sib phim. Cov txheej txheem tsim khoom yog tshwj xeeb heev. Nws pib nrog forging lossis precision casting ntawm cov hlau alloy blanks, xws li 18CrNiMo7-6, ua raws li kev txiav ntxhib, hobbing, lossis shaping los tsim cov iav pib. Cov txheej txheem siab heev xws li 5-axis machining, skiving, thiab hard cutting ua kom muaj qhov tseeb siab thiab qhov ua tiav ntawm qhov chaw. Tom qab kev kho cua sov xws li carburization (58–60 HRC), cov iav raug lapping lossis sib tsoo kom ua tiav qhov sib xyaw zoo meej ntawm pinion thiab iav.

Cov geometry ntawm Gleason spiral bevel gears yog txhais los ntawm ntau qhov tseem ceeb - lub kaum sab xis ntawm lub kauv, lub kaum sab xis ntawm lub siab, qhov deb ntawm lub suab, thiab qhov dav ntawm lub ntsej muag. Cov kev ntsuas no tau suav meej kom ntseeg tau tias cov qauv sib cuag hniav raug thiab kev faib khoom thauj. Thaum lub sijhawm tshuaj xyuas zaum kawg, cov cuab yeej xws li lub tshuab ntsuas kev sib koom tes (CMM) thiab kev tshuaj xyuas kev sib cuag hniav (TCA) xyuas kom meej tias cov iav teeb tsa ua tau raws li DIN 6 lossis ISO 1328-1 chav kawm raug.

Thaum ua haujlwm, Gleason spiralcov iav bevelmuab kev ua haujlwm zoo thiab ruaj khov txawm tias nyob rau hauv cov xwm txheej nyuaj. Cov hniav nkhaus muab kev sib cuag tas mus li, txo qhov kev ntxhov siab thiab kev hnav. Qhov no ua rau lawv zoo tagnrho rau cov khoom sib txawv hauv tsheb, cov thawv iav tsheb thauj khoom, cov tshuab hnyav, cov tshuab tsav nkoj, thiab cov cuab yeej hluav taws xob. Tsis tas li ntawd, lub peev xwm los kho cov qauv hniav thiab qhov deb ntawm kev teeb tsa tso cai rau cov engineers los ua kom zoo dua qhov tsim rau qhov tshwj xeeb torque, ceev, thiab qhov chaw txwv.

Gleason-hom kauv bevel iav - lub rooj xam tseem ceeb

| Khoom | Cov Qauv / Kev Qhia | Cov Hloov Pauv / Cov Lus Cim |

|---|---|---|

| Cov kev xaiv tswv yim | (z_1,\ z_2,\ m_n,\ \alpha_n,\ \Sigma,\ b,\ T) | Cov hniav pinion/iav (z); cov module ib txwm muaj (m_n); lub kaum sab xis siab ib txwm muaj (\alpha_n); lub kaum sab xis ntawm lub ncej (\Sigma); qhov dav ntawm lub ntsej muag (b); lub zog xa mus (T). |

| Qhov siv (nruab nrab) txoj kab uas hla | (d_i = z_i, m_n) | i = 1 (pinion), 2 (iav). Qhov nruab nrab/qhov siv tau hauv seem ib txwm. |

| Lub kaum sab xis ntawm lub khob hliav qab (cone) | (\delta_1,\ \delta_2) xws li (\delta_1+\delta_2=\Sigma) thiab (\dfrac{\sin\delta_1}{d_1}=\dfrac{\sin\delta_2}{d_2}) | Daws cov ces kaum ntawm lub khob hliav qab uas sib xws nrog cov hniav sib piv thiab lub kaum sab xis ntawm tus ncej. |

| Qhov deb ntawm lub cone (qhov deb ntawm lub suab apex) | (R = \dfrac{d_1}{2\sin\delta_1} = \dfrac{d_2}{2\sin\delta_2}) | Qhov deb ntawm lub cone apex mus rau lub voj voog suab ntsuas raws li generatrix. |

| Lub suab voj voog (ib txwm) | (p_n = \pi m_n) | Lub suab linear ntawm qhov seem ib txwm. |

| Module transverse (kwv yees li) | (m_t = \dfrac{m_n}{\cos\beta_n}) | (\beta_n) = lub kaum sab xis ib txwm muaj; hloov pauv ntawm cov seem ib txwm muaj thiab cov seem transverse raws li qhov xav tau. |

| Lub kaum sab xis kauv (qhov nruab nrab/kev sib raug zoo ntawm sab nraud) | (\tan\beta_t = \tan\beta_n \cos\delta_m) | (\delta_m) = lub kaum sab xis ntawm lub khob hliav qab; siv kev hloov pauv ntawm cov kaum sab xis ib txwm, cov kaum sab xis hla, thiab cov kaum sab xis ntawm lub kauv. |

| Kev pom zoo dav ntawm lub ntsej muag | (b = k_b, m_n) | (k_b) feem ntau xaiv los ntawm 8 txog 20 nyob ntawm qhov loj me thiab daim ntawv thov; sab laj nrog kev xyaum tsim qauv kom paub meej tias muaj tus nqi tseeb. |

| Ntxiv (nruab nrab) | (ib \approx m_n) | Tus qauv kwv yees qhov tob tag nrho; siv cov lus qhia sib piv ntawm cov hniav kom meej rau cov nqi tseeb. |

| Sab nraud (qhov taub) txoj kab uas hla | (d_{o,i} = d_i + 2a) | kuv = 1,2 |

| Txoj kab uas hla ntawm cov cag | (d_{f,i} = d_i – 2h_f) | (h_f) = dedendum (los ntawm cov qauv ntawm lub iav). |

| Cov hniav sib npaug tuab (kwv yees li) | (s \approx \dfrac{\pi m_n}{2}) | Rau cov qauv geometry bevel siv cov tuab kho los ntawm cov lus qhia hniav kom raug. |

| Lub zog tangential ntawm lub voj voog suab | (F_t = \dfrac{2T}{d_p}) | (T) = lub zog tig; (d_p) = lub suab ntawm lub suab (siv cov chav sib xws). |

| Kev ntxhov siab ntawm kev khoov (yooj yim) | (\sigma_b = \dfrac{F_t \cdot K_O \cdot K_V}{b \cdot m_n \cdot Y}) | (K_O) = qhov hnyav tshaj, (K_V) = qhov hnyav hloov pauv, (Y) = qhov hnyav ntawm daim ntawv (qhov khoov geometry). Siv tag nrho AGMA/ISO bending equation rau kev tsim qauv. |

| Kev ntxhov siab ntawm kev sib cuag (Hertz-hom, yooj yim) | (\sigma_H = C_H \sqrt{\dfrac{F_t}{d_p , b} \cdot \dfrac{1}{\frac{1-\nu_1^2}{E_1}+\frac{1-\nu_2^2}{E_2}}}) | (C_H) geometry tsis hloov pauv, (E_i,\nu_i) cov khoom siv elastic moduli thiab Poisson ratios. Siv cov kab zauv sib cuag-kev ntxhov siab tag nrho rau kev txheeb xyuas. |

| Kev sib cuag piv (dav dav) | (\varepsilon = \dfrac{\text{arc of action}}{\text{base pitch}}) | Rau cov iav bevel xam siv pitch cone geometry thiab lub kaum sab xis ntawm lub kauv; feem ntau ntsuas nrog cov lus qhia tsim iav lossis software. |

| Tus naj npawb ntawm cov hniav virtual | (z_v \approx \dfrac{d}{m_t}) | Pab tau rau kev sib cuag / kev kuaj xyuas qis dua; (m_t) = transverse module. |

| Kev kuaj xyuas cov hniav tsawg kawg nkaus / kev txiav qis dua | Siv cov mob hniav tsawg kawg nkaus raws li lub kaum sab xis ntawm lub kauv, lub kaum sab xis ntawm lub zog thiab qhov sib piv ntawm cov hniav | Yog tias (z) qis dua qhov tsawg kawg nkaus, yuav tsum tau siv cov cuab yeej tshwj xeeb lossis cov cuab yeej txiav qis dua. |

| Kev teeb tsa tshuab/txiav (kauj ruam tsim qauv) | Txheeb xyuas lub kaum sab xis ntawm lub taub hau txiav, kev tig ntawm lub txaj thiab kev ntsuas los ntawm cov qauv ntawm lub iav | Cov chaw no yog los ntawm cov qauv iav thiab lub kaw lus txiav; ua raws li cov txheej txheem tshuab / cuab yeej. |

Cov thev naus laus zis niaj hnub no, xws li CNC bevel gear txiav thiab sib tsoo tshuab, ua kom muaj qhov zoo sib xws thiab kev sib pauv tau. Los ntawm kev koom ua ke computer-aided design (CAD) thiab kev sim ua qauv, cov tuam txhab tsim khoom tuaj yeem ua qhov rov qab engineering thiab virtual sim ua ntej kev tsim khoom tiag tiag. Qhov no txo lub sijhawm ua khoom thiab tus nqi thaum txhim kho qhov tseeb thiab kev ntseeg siab.

Hauv kev xaus lus, Gleason spiral bevel gears sawv cev rau kev sib xyaw ua ke zoo meej ntawm geometry siab heev, lub zog ntawm cov khoom siv, thiab kev tsim khoom raug. Lawv lub peev xwm los xa cov hluav taws xob du, ua haujlwm tau zoo, thiab ruaj khov tau ua rau lawv yog ib qho khoom tseem ceeb hauv cov tshuab tsav tsheb niaj hnub. Txawm hais tias siv rau hauv kev lag luam tsheb, kev lag luam, lossis aerospace, cov iav no txuas ntxiv txhais qhov zoo tshaj plaws hauv kev txav mus los thiab kev ua haujlwm kho tshuab.

Lub sijhawm tshaj tawm: Lub Kaum Hli-24-2025