Hauv ntiaj teb ntawm kev ua haujlwm raug, CNC rotary rooj ua lub luag haujlwm tseem ceeb hauv kev ua kom muaj kev ntsuas qhov tseeb, kev sib hloov tas mus li, thiab kev ua haujlwm ntau-axis. Txawm hais tias siv rau hauv cov chaw machining ntsug, cov chaw machining kab rov tav, 5 axis systems, lossis cov khoom siv qhov chaw siab, cov rooj rotary vam khom ntau rau cov khoom siv kis tau zoo heev. Ntawm cov khoom no, cov iav yog cov ntsiab lus tseem ceeb uas txiav txim siab qhov tseeb, kev ruaj khov, lub peev xwm torque, kev ua haujlwm ceev, thiab kev ruaj khov mus sij hawm ntev.

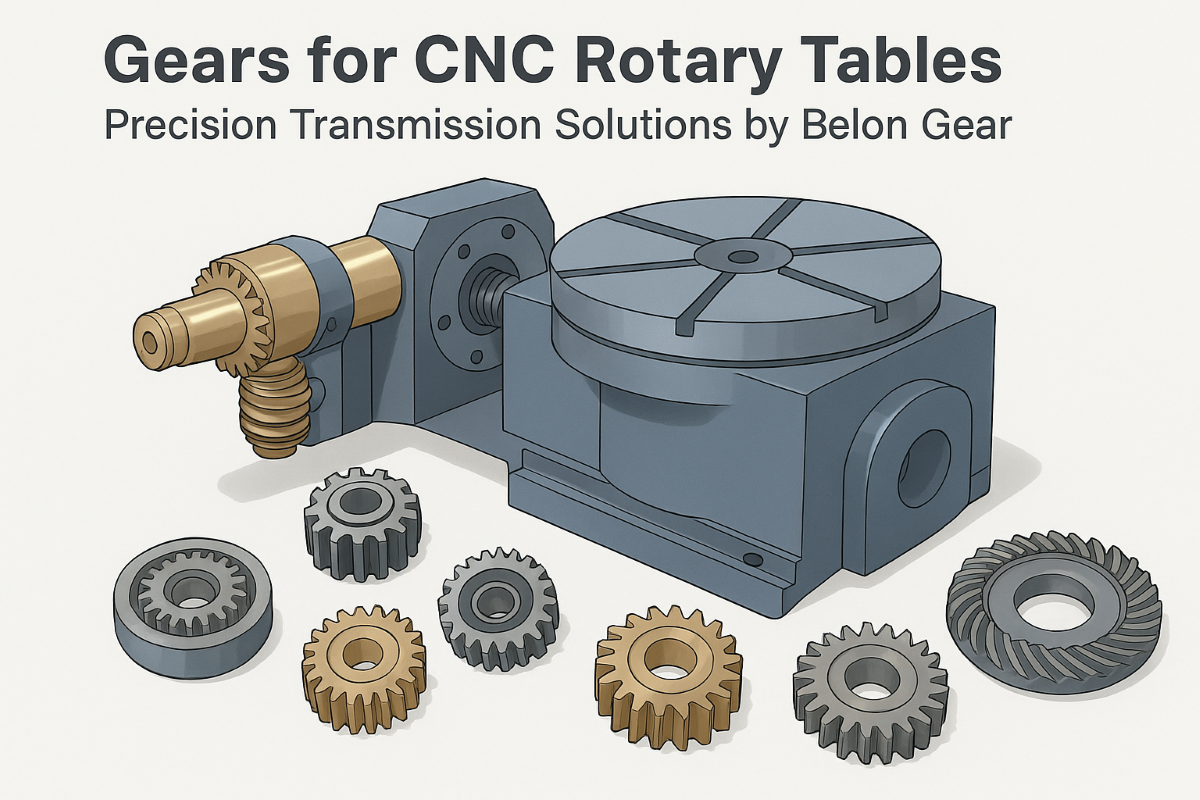

Ua ib lub tuam txhab thoob ntiaj teb uas muab cov iav precision, Belon Gear muab cov iav tiav uas tsim tshwj xeeb rau cov chaw tsim khoom rotary table, cov neeg tsim tshuab CNC, cov tuam txhab automation, thiab cov chaw muag khoom high precision positioning system. Peb cov iav yog tsim nrog kev kam rau siab, cov hniav zoo tshaj plaws, thiab kev ruaj khov tsim rau cov khoom hnyav thiab lub neej ntev.

Tsab xov xwm no muab ib daim ntawv qhia txog cov iav uas feem ntau siv hauv cov rooj sib hloov, txhua hom ua haujlwm li cas, thiab cov txiaj ntsig tshwj xeeb uas Belon Gear muab rau kev lag luam.

1. Cov iav cab thiab cov ncej cab — Lub zog tseem ceeb ib txwm muaj

Cov iav kabCov txheej txheem tau yog cov qauv kis tau siv dav tshaj plaws hauv cov rooj sib hloov. Lawv tseem nrov heev, tshwj xeeb tshaj yog rau cov rooj ntsuas qhov nruab nrab, vim lawv cov txiaj ntsig kho tshuab tshwj xeeb.

Lawv Ua Haujlwm Li Cas

Ib tug kabtus ncejtsav lub log kab laug sab (ib hom iav helical nrog cov hniav nkhaus). Vim yog qhov sib txhuam ntawm cov xov kab laug sab thiab cov hniav log, lub kaw lus ua tiav qhov sib piv txo qis siab hauv ib theem.

Cov txiaj ntsig tseem ceeb

- Qhov piv txo qis siab (i = 1: 40 ~ 1: 120)

-

Kev muaj peev xwm xauv tus kheej, txhim kho kev ruaj ntseg thiab kev nyab xeeb

-

Kev ua haujlwm du

-

Tsim qauv me me

Cov ntawv thov

-

Cov rooj sib hloov CNC txheem

-

4 axis indexing rooj

-

Cov txheej txheem ua haujlwm hnyav

Belon Gear Capability

Belon Gear tsim cov log tsheb ciav hlau thiab cov ncej tsheb ciav hlau nrog:

-

Cov chav kawm precision txog li DIN 6

-

Tooj liab, hlau alloy, thiab cov ntaub ntawv carburized

-

Kev sib tsoo thiab lapping xaiv rau kev du thiab ruaj khov

-

Cov qauv profiles tshwj xeeb tau tsim kho kom zoo rau lub peev xwm torque thiab txo qhov kub

Peb cov iav kab mob tau tsim los kom txo qhov hnav thiab tswj qhov tseeb txawm tias nyob hauv cov voj voog ua haujlwm tas mus li.

2. Cov Khoom Siv Hluav Taws Xob Planetary — Kev Kis Fais Fab Uas Muaj Kev Ntsuas Siab, Muaj Zog Siab

Cov rooj sib hloov CNC niaj hnub - tshwj xeeb tshaj yog cov qauv ceev ceev - feem ntau siv cov iav reducers planetary ua ke nrog servo motors.

Vim li cas Planetary Gears thiaj nrov

Cov iav planetary muab cov hauv qab no:

-

Siab torque ceev

-

Kev sib kis tau zoo heev

-

Qhov backlash qis heev (tuaj yeem ncav cuag <3 arcmin)

-

Kev sib sau ua ke zoo heev thiab kev faib khoom thauj khoom

Hauv cov rooj sib hloov 4-axis thiab 5-axis uas muaj qhov tseeb siab, feem ntau siv lub planetary stage ua ntej lub kaw lus tsav ncaj qha lossis lub ncej loj hnyav.

Lub zog ntawm Belon Gear hauv Planetary Systems

Belon Gear tsim cov khoom siv precision planetary gear xws li:

-

Cov iav hnub ci

-

Cov iav nplhaib

-

Cov neeg nqa khoom sib xyaw ua ke

Cov peev xwm suav nrog:

-

Cov modules los ntawm m0.5 txog m12

-

Kev hloov kho cov hniav profile rau kev txo suab nrov

-

Cov hlau ua los ntawm cov hlau sib xyaw ua ke uas tau kho cua sov rau kev tiv taus kev qaug zog mus sij hawm ntev

-

Ultra qis backlash precision sib tsoo

Peb cov iav siv dav hauv cov rooj sib hloov servo, caj npab robotic, thiab cov tshuab tso chaw tsis siv neeg.

3. Cov Kauv Sib Npaug thiab Zerol Bevel Gears — Qhov tseem ceeb rau 90 ° Fais Fab Hloov Chaw

Cov rooj sib hloov feem ntau xav tau qhov kev teeb tsa kis tau tus mob L-zoo li (90 degree), tshwj xeeb tshaj yog thaum ntsia ncaj qha rau cov cuab yeej siv tshuab. Qhov no yog qhov uas cov iav sib dhos thiab cov iav sib dhos Zerol tseem ceeb heev.

Vim li cas Bevel Gears thiaj siv tau

-

Hloov kev taw qhia ntawm lub zog kis tau tus mob

-

Muab lub peev xwm torque siab

-

Muab kev ua haujlwm du thiab ntsiag to

-

Txhawb kev nkag mus rau hauv lub cev muaj zog servo high-speed

Kauv Vs Zerol Bevel Gears

-

Kauv Bevel GearCov hniav nkhaus, cov meshing du, zoo tagnrho rau kev kub ceev thiab cov khoom hnyav

-

Zerol Bevel Gear: Lub kaum sab xis ntawm lub kauv uas yog xoom degree, sib xyaw ntawm lub kauv thiab lub bevel ncaj; suab nrov qis dua, ruaj khov dua nyob rau hauv cov xwm txheej indexing meej

Cov txiaj ntsig ntawm Belon Gear

Belon Gear tshwj xeeb hauv kev tsim cov iav bevel siv:

-

Gleason thiab Klingelnberg txiav tshuab

-

Kev sib tsoo raug txog li DIN 5

-

Cov modules los ntawm m0.5 txog m35

-

Txoj kab uas hla mus txog 1600 hli +

Cov iav no siv dav hauv:

-

Cov khoom sib dhos C-axis

-

Cov ntsuas siab torque

-

Tsib-axis machining taub hau

4. Spur thiab Helical Gears — Cov Cheebtsam Pabcuam Kis

Thaum lub sijhawm tig tseem ceeb feem ntau vam khom cov kab mob worm lossis planetary systems, spur thiab helical gears kuj ua lub luag haujlwm tseem ceeb.

Cov Hom Iav Siv Hauv Cov Rooj Sib Hloov

| Hom iav | Txoj Haujlwm Siv | Lub Luag Haujlwm Tseem Ceeb |

|---|---|---|

| Cov iav cab & cov ncej cab | Tsav tsheb tseem ceeb | Qhov piv txwv txo qis loj, xauv tus kheej, qhov chaw meej |

| Planetary Gear Reducer | Nruab nrab ntawm lub cev muaj zog thiab lub spindle | Siab torque, high-precision ceev txo |

| Helical Bevel / Zerol Bevel Iav | Kev sib kis hloov pauv kev taw qhia | 90 ° fais fab hloov pauv, siab precision, suab nrov tsawg |

| Spur /Cov iav helical | Kev tsav tsheb pab, lub tshuab nres | Lub zog kis tau los yog clamping system |

| Harmonic Gear Drive | Cov rooj sib hloov siab heev | Kev tso kawm ntawm qib micron, kev ua haujlwm siab heev |

Cov Kev Siv Ib Txwm Muaj

-

Kev sib kis sab hauv ntawm lub cev muaj zog thiab lub kaw lus clamping

-

Kev ua haujlwm ntawm lub tshuab nres

-

Kev sib txuas ntawm encoder

-

Cov theem txo qis thib ob

Vim Li Cas Lawv Thiaj Tseem Ceeb

Txawm hais tias cov iav no tsis yog lub zog tsav tseem ceeb tas li, lawv qhov zoo cuam tshuam ncaj qha rau:

-

Kev ruaj khov ntawm backlash

-

Rov ua dua tau

-

Kev ua haujlwm ntawm lub nres

-

Cov suab nrov

Belon Gear tsim cov iav spur thiab helical nrog:

-

Kev sib tsoo profile

-

Cov kev xaiv khoom siv carbide

-

Muaj peev xwm iav sab hauv / sab nraud

-

Kev hloov kho hniav kom raug rau kev sib npaug ntawm qhov hnyav

5. Harmonic Gears — Ultra-High Precision rau Semiconductor-Grade Rotary Tables

Hauv cov rooj sib hloov ceev heev uas siv rau kev ua cov khoom siv semiconductor, kev siv laser, kev teeb tsa optical, lossis cov txheej txheem metrology, cov iav tsav harmonic yuav siv tau.

Cov txiaj ntsig

-

Ze li ntawm xoom backlash (<1 arcsec)

-

Qhov tseeb ntawm qhov chaw siab heev

-

Tsim me me, sib dua

-

Cov piv txwv txo qis siab

Qhov Chaw Lawv Siv

-

Cov platform micro-indexing

-

Cov khoom siv tuav wafer siab

-

Cov theem tig kho qhov muag ntau-axis

Belon Gear muab cov hniav iav sib xws nrog flex-spline thiab cov khoom sib xws.

Vim li cas cov chaw tsim khoom lag luam xaiv Belon Gear rau Rotary Table Gear Solutions

1. Kev Tsim Khoom Siv Siab Tshaj Plaws

Belon Gear xa cov kev kam rau ua raws li:

-

DIN 5–7 rau cov iav bevel

-

DIN 4–6 rau cov iav cylindrical

-

Kev sib tsoo precision rau kev ua suab nrov qis

2. Kev Tshawb Nrhiav Khoom Siv Tag Nrho

Cov ntaub ntawv muaj xws li:

-

20CrMnTi

-

8620

-

18CrNiMo7-6

-

Tooj dag, tooj dag (rau cov log tsheb ciav hlau)

Txhua pawg yog tag nrho traceable.

3. Kev Tsim Kho Rov Qab Iav rau OEM Hloov

Belon Gear kuj txhawb nqa cov neeg siv khoom uas xav tau:

-

Tsim rov qab raws li cov iav hnav

-

Kev hloov kho khoom siv

-

Kev ua kom zoo dua qhov nyuaj

-

Kev txhim kho backlash

4. Kev daws teeb meem tshwj xeeb rau txhua hom rooj sib hloov

Xws li:

-

Cov rooj sib hloov ua haujlwm hnyav

-

Cov rooj sib hloov ua haujlwm ceev ceev

-

Cov rooj sib hloov DD lub cev muaj zog

-

4-axis thiab 5-axis CNC rotary systems

-

Kev ntsuas qhov muag pom tseeb

-

Cov turntables tso rau qhov chaw tsis siv neeg

5. Kev Zoo Sib Xws, Kev Xa Khoom Thoob Ntiaj Teb

Belon Gear muab cov khoom siv rau cov neeg siv khoom thoob plaws North America, Tebchaws Europe, South America, thiab Asia, txhawb nqa cov neeg tsim tshuab thiab cov tuam txhab automation kev lag luam nrog cov kev daws teeb meem iav ntev ntev.

Xaus lus

Cov rooj sib hloov CNC vam khom cov iav uas tau tsim los ntawm kev ua haujlwm kom raug, ruaj khov, thiab txhim khu kev qha. Txawm hais tias lub kaw lus siv cov iav tsav tsheb ib txwm muaj, lub iav txo qis siab, lub iav sib kis, lossis cov iav harmonic siab heev, qhov zoo ntawm txhua lub iav txiav txim siab ncaj qha rau kev ua haujlwm ntawm lub rooj sib hloov.

Nrog rau kev muaj peev xwm tsim khoom siab heev, kev tswj hwm zoo nruj, thiab kev txawj ntse tob hauv kev tsim kho iav kev lag luam, Belon Gear txuas ntxiv txhawb nqa cov neeg siv khoom thoob ntiaj teb nrog cov kev daws teeb meem iav tsim tshwj xeeb rau cov rooj sib hloov thiab cov ntawv thov kis tau zoo.

Yog tias koj qhov project xav tau cov khoom siv iav zoo thiab txhim khu kev qha rau lub rooj sib hloov, Belon Gear npaj txhij los txhawb koj txij li tsim qauv mus txog thaum xa khoom.

Lub sijhawm tshaj tawm: Kaum Ib Hlis-24-2025