Cov iavKev hloov kho cov hniav yog ib qho tseem ceeb ntawm kev tsim cov iav, txhim kho kev ua tau zoo los ntawm kev txo cov suab nrov, kev co, thiab kev ntxhov siab. Tsab xov xwm no tham txog cov kev suav tseem ceeb thiab kev xav txog kev koom nrog hauv kev tsim cov hniav iav hloov kho.

1. Lub Hom Phiaj ntawm Kev Hloov Kho Cov Hniav

Kev hloov kho cov qauv hniav feem ntau yog siv los them rau qhov kev hloov pauv ntawm kev tsim khoom, kev tsis sib haum, thiab kev hloov pauv elastic thaum muaj kev thauj khoom. Lub hom phiaj tseem ceeb suav nrog:

- Txo qhov yuam kev ntawm kev sib kis

- Txo cov suab nrov thiab kev co ntawm cov iav

- Txhim kho kev faib khoom thauj khoom

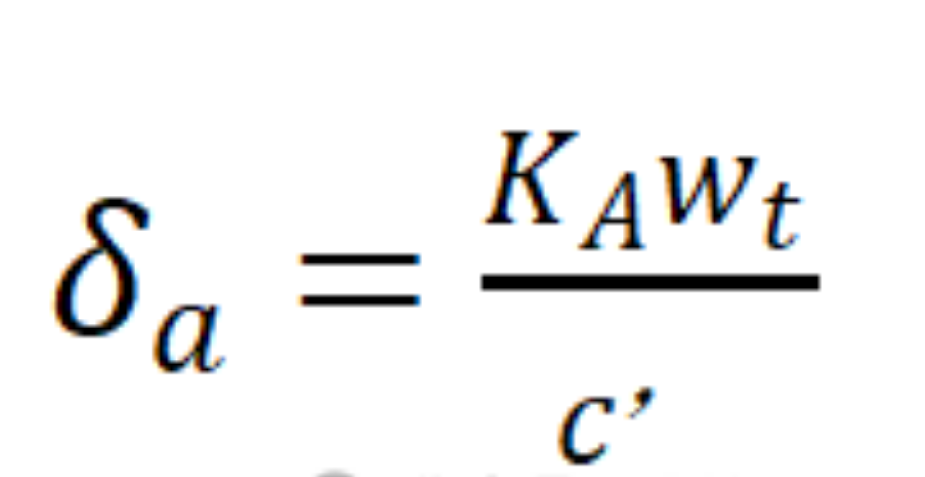

- Ua kom lub neej ntawm cov iav ntev dua Raws li lub ntsiab lus ntawm qhov sib zog ntawm cov iav, qhov kev hloov pauv elastic ntawm cov hniav iav tuaj yeem kwv yees los ntawm cov mis hauv qab no: δa - cov hniav elastic deformation, μm; KA - Siv qhov tseem ceeb, xa mus rau ISO6336-1; wt - thauj khoom ib chav dav ntawm cov hniav, N / hli, wt = Ft / b; Ft - lub zog tangential ntawm cov iav, N; b - qhov dav ntawm cov hniav zoo ntawm cov iav, hli; c '- ib khub hniav mesh stiffness, N / (mm · μm); cγ - Qhov nruab nrab meshing stiffness, N / (mm · μm).Spur Gear

Bevel Gear

- Kev Pab Txhawb Nqa Lub Tswv Yim: Tshem tawm cov khoom siv los ntawm qhov kawg ntawm cov hniav iav kom tiv thaiv kev cuam tshuam thaum lub sijhawm meshing.

- Kev Kho Mob Hauv Paus: Hloov kho qhov seem hauv paus kom txo qhov kev ntxhov siab thiab txhim kho lub zog.

- Kev siv lead ua lub kaus momSiv me ntsis nkhaus raws qhov dav ntawm cov hniav kom haum rau qhov tsis sib luag.

- Kev Kho Kom Zoo Nkauj: Qhia txog qhov nkhaus raws li qhov profile involute kom txo cov kev ntxhov siab ntawm ntug kev sib cuag.

3. Kev Xam Xaj Tsim Qauv

Kev hloov kho cov hniav iav feem ntau yog xam los ntawm kev siv cov txheej txheem tshuaj xyuas, kev sim ua qauv, thiab kev sim ua pov thawj. Cov kev ntsuas hauv qab no raug txiav txim siab:

- Tus Nqi Hloov Kho (Δ)Qhov tob ntawm cov khoom siv uas raug tshem tawm ntawm qhov chaw hniav, feem ntau yog li ntawm 5 txog 50 microns nyob ntawm cov xwm txheej ntawm kev thauj khoom.

- Qhov Cuam Tshuam ntawm Kev Faib Khoom (K): Txheeb xyuas seb lub zog sib cuag raug faib li cas thoob plaws qhov chaw ntawm cov hniav hloov kho.

- Kev Kis Tau Yuam Kev (TE)Txhais tias yog qhov sib txawv ntawm qhov kev txav mus los tiag tiag los ntawm qhov kev txav mus los zoo tagnrho, txo qis los ntawm kev hloov kho profile zoo tshaj plaws.

- Kev Tshawb Fawb Txog Cov Khoom Siv Finite (FEA): Siv los ua qauv qhia txog kev faib tawm kev ntxhov siab thiab lees paub qhov kev hloov kho ua ntej tsim khoom.

4. Kev Xav Txog Kev Tsim Qauv

- Cov xwm txheej thauj khoomTus nqi ntawm kev hloov kho nyob ntawm qhov kev thauj khoom siv thiab kev hloov pauv uas xav tau.

- Kev Tsim Khoom Siv Tau: Kev ua kom raug thiab kev sib tsoo yog qhov yuav tsum tau ua kom tiav qhov kev hloov kho xav tau.

- Cov Khoom Siv: Qhov tawv thiab elasticity ntawm cov khoom siv iav cuam tshuam rau qhov ua tau zoo ntawm kev hloov kho profile.

- Ib puag ncig ua haujlwm: Cov ntawv thov ceev thiab thauj khoom ntau yuav tsum tau hloov kho kom meej dua.

5. Kev hloov kho cov hniav yog qhov tseem ceeb rau kev ua kom cov iav ua haujlwm tau zoo, txo cov suab nrov, thiab txhim kho kev ruaj khov. Kev hloov kho zoo, txhawb nqa los ntawm kev xam thiab kev ua piv txwv raug, ua kom ntseeg tau tias lub zog ua haujlwm tau ntev thiab ua haujlwm tau zoo hauv ntau yam kev siv.

Los ntawm kev xav txog cov xwm txheej thauj khoom, cov khoom siv, thiab cov txheej txheem tsim khoom raug, cov engineers tuaj yeem ua tiav qhov kev ua tau zoo tshaj plaws thaum txo cov teeb meem kev ua haujlwm.

Lub sijhawm tshaj tawm: Lub Ob Hlis-11-2025