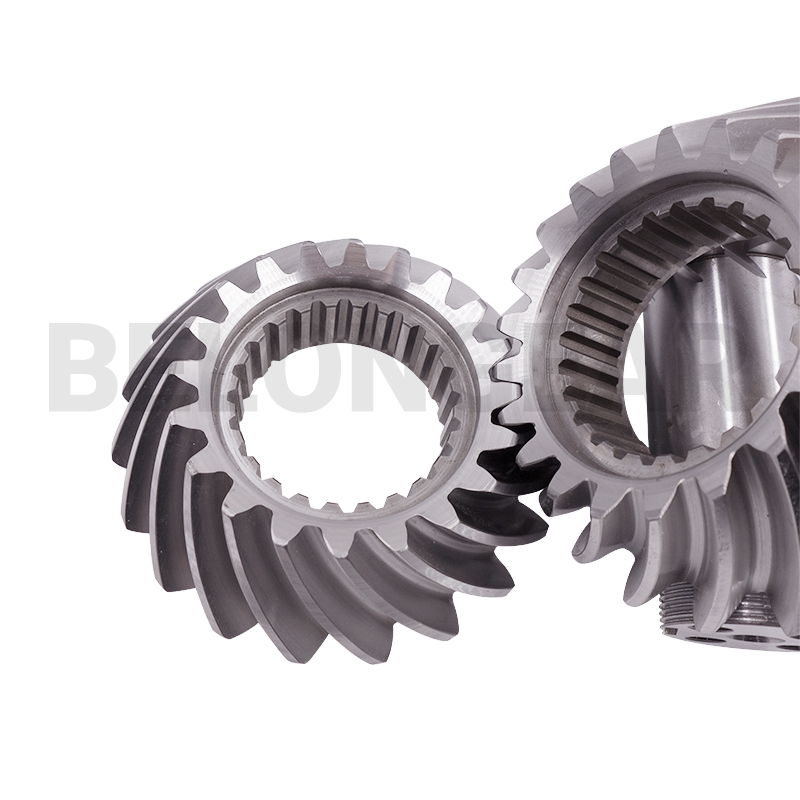

Cov iav miterua lub luag haujlwm tseem ceeb hauv cov tshuab vim lawv ua haujlwm ua cov khoom tseem ceeb rau kev xa lub zog ntawm cov ncej uas sib tshuam ntawm lub kaum sab xis. Kev tsim cov iav no tso cai rau kev hloov pauv lub kaum sab xis hauv kev taw qhia ntawm kev tig, ua rau lawv haum rau ntau yam kev siv. Nov yog kev tshawb nrhiav ntawm lawv lub luag haujlwm hauv cov tshuab, nrog rau kev tsom mus rau kev xa lub zog ntawm cov ncej perpendicular:

1. Kev Kis Fais Fab

Ib qho ntawm cov luag haujlwm tseem ceeb ntawmcov iav miter Hauv cov tshuab yog kev xa hluav taws xob. Lawv siv los xa lub zog tig tau zoo ntawm cov ncej uas tau teeb tsa ntawm lub kaum sab xis 90-degree rau ib leeg. Qhov no yog qhov tshwj xeeb tshaj yog nyob rau hauv cov xwm txheej uas qhov chaw txwv lossis kev tsim qauv yuav tsum tau hloov pauv hauv kev coj ntawm lub zog ntws.

2. Kev Them Nyiaj Rau Qhov Tsis Sib Haum Ntawm Ncej:

Cov khoom siv tshuab tsis yog ib txwm sib dhos zoo tag nrho, thiabcov iav mitermuaj txiaj ntsig zoo rau kev them nyiaj rau qhov tsis sib xws me ntsis ntawm cov ncej perpendicular. Cov hniav iav ntawm miter iav koom tes zoo, tso cai rau kev hloov pauv lub zog txawm tias thaum cov ncej tsis sib dhos zoo.

3. Kev Siv Tau Ntau Yam Hauv Daim Ntawv Thov:

Cov iav miternrhiav kev siv rau ntau hom tshuab, suav nrog tab sis tsis txwv rau cov tshuab conveyor, tshuab milling, thiab tshuab luam ntawv. Lawv qhov kev hloov pauv ua rau lawv haum rau ntau qhov chaw lag luam uas xav tau kev xa hluav taws xob zoo ntawm cov ces kaum sab xis.

4. Tsim Qauv Me Me:

Kev tsim qauv compact thiab chaw txuag tau ntawmcov iav miterua rau lawv zoo tagnrho rau cov tshuab uas qhov chaw yog qhov tseem ceeb xav txog. Lawv lub peev xwm los hloov qhov kev taw qhia ntawm lub zog xa mus rau hauv qhov chaw kaw yog qhov tseem ceeb rau kev tsim qauv compact ntawm ntau yam tshuab.

5. Kev Ntsuas Tseeb thiab Kev Ntsuas Tseeb:

Cov iav miter feem ntau siv rau hauv cov tshuab uas xav tau kev ua kom raug thiab raug. Lawv cov hniav sib txuas ua ke muab txoj hauv kev ruaj khov thiab txhim khu kev qha ntawm kev xa hluav taws xob, ua kom ntseeg tau tias kev txav mus los tau hloov pauv nrog qhov rov qab thiab kev ua si tsawg kawg nkaus.

6. Kev txo iav thiab kev tswj ceev:

Hauv cov tshuab uas xav tau kev txo qis iav lossis kev tswj ceev, cov iav miter tuaj yeem yog ib feem ntawm lub kaw lus uas kho qhov ceev thiab lub zog ntawm cov ncej tso zis piv rau cov ncej nkag. Qhov no yog qhov tshwj xeeb tshaj yog nyob rau hauv cov ntawv thov uas xav tau kev ua haujlwm sib txawv.

7. Cov Khoom Siv Hauv Kev Lag Luam Thiab Kev Tsim Khoom:

Cov iav miter feem ntau siv rau hauv ntau yam khoom siv hauv kev lag luam thiab kev tsim khoom, xws li cov kab sib dhos, cov tshuab ntim khoom, thiab cov tshuab textile. Lawv lub luag haujlwm hauv cov ntawv thov no suav nrog kev hloov pauv kev coj ntawm lub zog ntws kom zoo thiab ntseeg tau.

Hauv kev xaus lus, cov iav miter ua lub luag haujlwm tseem ceeb hauv tshuab los ntawm kev ua kom muaj kev sib kis tau zoo ntawm lub zog ntawm cov ncej perpendicular. Lawv qhov kev hloov pauv tau yooj yim, kev tsim qauv me me, thiab lub peev xwm los them rau qhov tsis sib xws ua rau lawv yog cov khoom muaj nqis hauv ntau yam kev siv hauv kev lag luam, pab txhawb rau kev ua haujlwm zoo thiab txhim khu kev qha ntawm cov tshuab hauv ntau qhov chaw sib txawv.

Lub sijhawm tshaj tawm: Lub Kaum Ob Hlis-05-2023