Ntau qhov ntawmcov iav txo zog tshiabthiabcov iav tshebQhov project yuav tsum tau siv tshuaj tua peening tom qab sib tsoo iav, uas yuav ua rau qhov zoo ntawm cov hniav nto tsis zoo, thiab txawm tias cuam tshuam rau kev ua haujlwm ntawm NVH ntawm lub system. Daim ntawv no kawm txog qhov roughness ntawm cov hniav nto ntawm cov txheej txheem shot peening sib txawv thiab cov khoom sib txawv ua ntej thiab tom qab shot peening. Cov txiaj ntsig qhia tau tias shot peening yuav ua rau qhov roughness ntawm cov hniav nto nce ntxiv, uas cuam tshuam los ntawm cov yam ntxwv ntawm cov khoom, cov txheej txheem shot peening thiab lwm yam; Nyob rau hauv cov txheej txheem ntau lawm uas twb muaj lawm, qhov roughness ntawm cov hniav nto siab tshaj plaws tom qab shot peening yog 3.1 npaug ntawm ua ntej shot peening. Kev cuam tshuam ntawm qhov roughness ntawm cov hniav nto rau kev ua haujlwm ntawm NVH tau tham txog, thiab cov kev ntsuas los txhim kho qhov roughness tom qab shot peening tau muab tso rau.

Hauv qab no yog cov ntsiab lus tseem ceeb, tsab ntawv no piav qhia txog peb yam tseem ceeb hauv qab no:

Kev cuam tshuam ntawm cov txheej txheem txhaj tshuaj peening rau qhov roughness ntawm cov hniav;

Qhov degree ntawm kev txhaj tshuaj peening ntawm qhov roughness ntawm cov hniav nyob rau hauv cov txheej txheem ntau lawm uas twb muaj lawm;

Kev cuam tshuam ntawm qhov roughness ntawm cov hniav ntawm qhov chaw ntawm NVH kev ua tau zoo thiab kev ntsuas los txhim kho qhov roughness tom qab txhaj tshuaj peening.

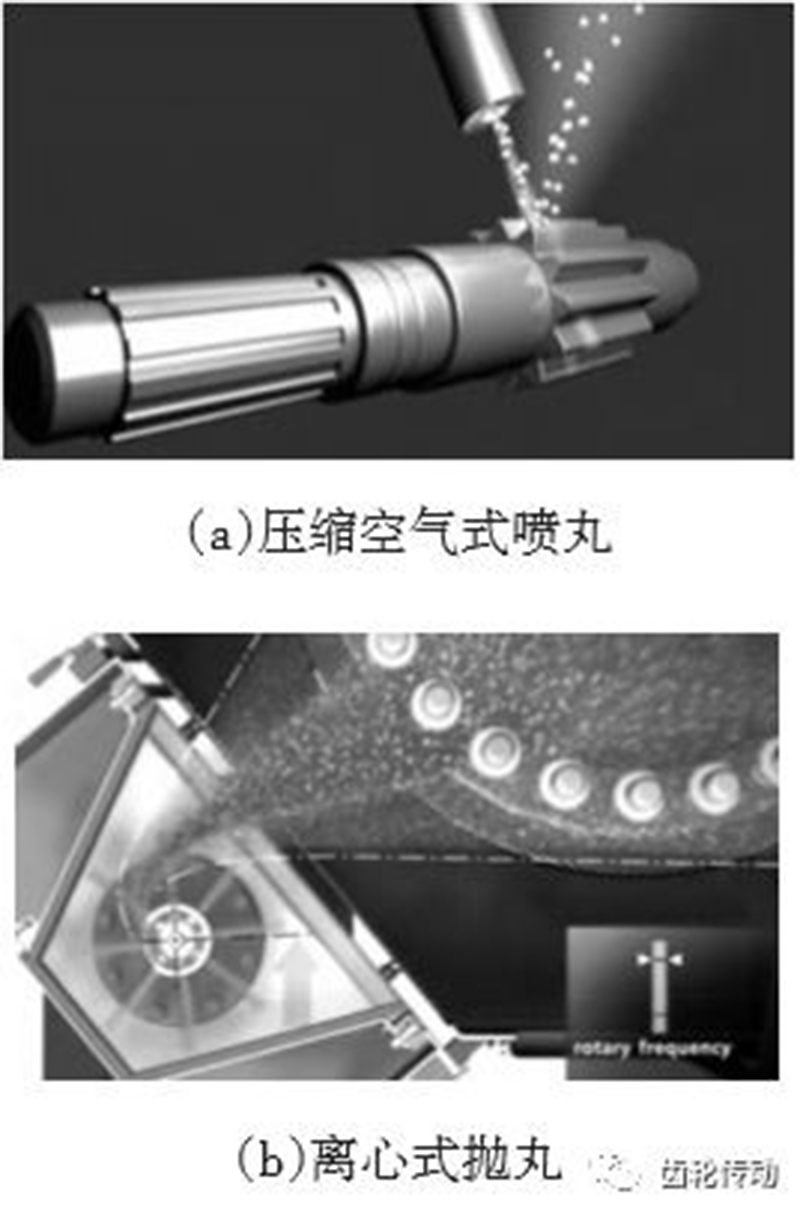

Kev txhaj tshuaj peening yog hais txog cov txheej txheem uas ntau lub foob pob me me uas muaj zog thiab txav ceev ceev ntaus rau ntawm qhov chaw ntawm cov khoom. Nyob rau hauv qhov kev cuam tshuam ceev ceev ntawm lub foob pob, qhov chaw ntawm qhov khoom yuav tsim cov qhov thiab cov yas deformation yuav tshwm sim. Cov koom haum nyob ib puag ncig cov qhov yuav tiv taus qhov kev hloov pauv no thiab tsim cov kev ntxhov siab compressive seem. Kev sib tshooj ntawm ntau lub qhov yuav tsim ib txheej compressive seem compressive ntawm qhov chaw ntawm qhov khoom, yog li txhim kho lub zog qaug zog ntawm qhov khoom. Raws li txoj kev tau txais kev ceev ceev los ntawm kev txhaj tshuaj, kev txhaj tshuaj peening feem ntau muab faib ua compressed air shot peening thiab centrifugal shot peening, raws li pom hauv Daim Duab 1.

Kev siv cua compressed shot peening siv cua compressed ua lub zog los txau cov mos txwv los ntawm rab phom; Centrifugal shot blasting siv lub cev muaj zog los tsav lub impeller kom tig ntawm qhov ceev ceev kom pov cov mos txwv. Cov txheej txheem tseem ceeb ntawm kev siv shot peening suav nrog lub zog saturation, kev npog thiab cov khoom siv shot peening (khoom siv, qhov loj me, cov duab, qhov nyuaj). Lub zog saturation yog ib qho parameter los piav qhia lub zog shot peening, uas yog qhia los ntawm qhov siab arc (piv txwv li qhov degree khoov ntawm Almen test piece tom qab shot peening); Tus nqi npog yog qhov sib piv ntawm thaj chaw uas npog los ntawm qhov av tom qab shot peening rau tag nrho thaj chaw ntawm thaj chaw shot peening; Cov khoom siv shot peening feem ntau siv suav nrog cov hlau txiav hlau shot, hlau cam khwb cia shot, ceramic shot, iav shot, thiab lwm yam. Qhov loj me, cov duab thiab qhov nyuaj ntawm cov khoom siv shot peening muaj ntau qib sib txawv. Cov kev cai dav dav rau cov khoom siv kis tau tus kheej tau qhia hauv Rooj 1.

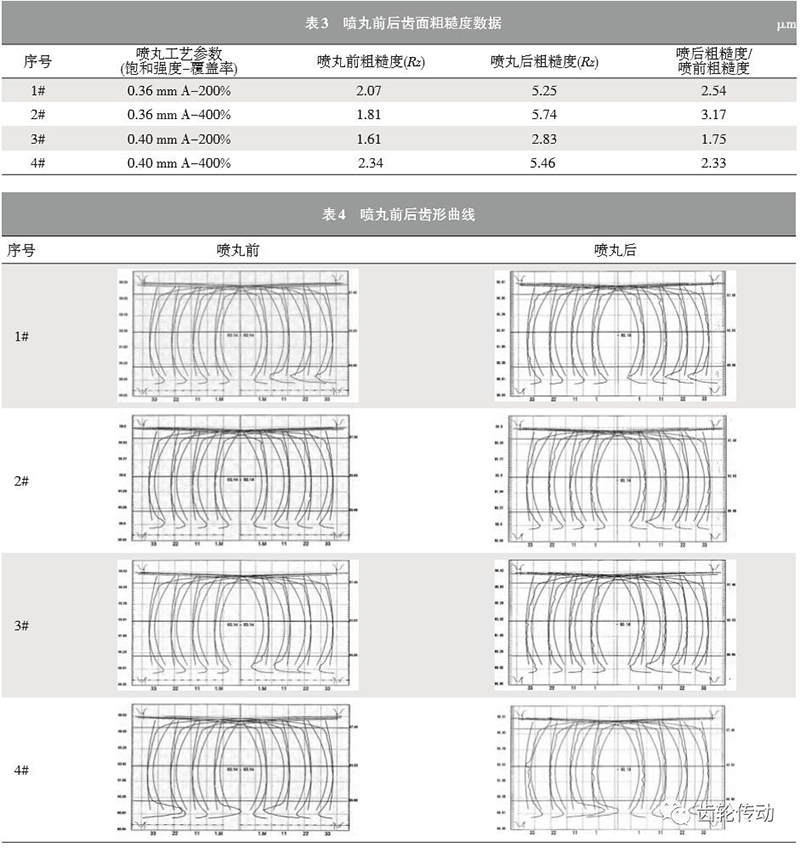

Qhov seem sim yog lub iav nruab nrab 1/6 ntawm qhov project hybrid. Cov qauv iav tau qhia hauv Daim Duab 2. Tom qab sib tsoo, qhov microstructure ntawm cov hniav yog Qib 2, qhov nyuaj ntawm qhov chaw yog 710HV30, thiab qhov tob ntawm cov txheej tawv tawv yog 0.65 hli, tag nrho nyob rau hauv cov kev cai lij choj. Qhov roughness ntawm cov hniav ua ntej tua peening tau qhia hauv Rooj 3, thiab qhov tseeb ntawm cov hniav profile tau qhia hauv Rooj 4. Nws tuaj yeem pom tias qhov roughness ntawm cov hniav ua ntej tua peening yog qhov zoo, thiab cov hniav profile nkhaus yog du.

Txoj kev npaj xeem thiab cov kev ntsuas xeem

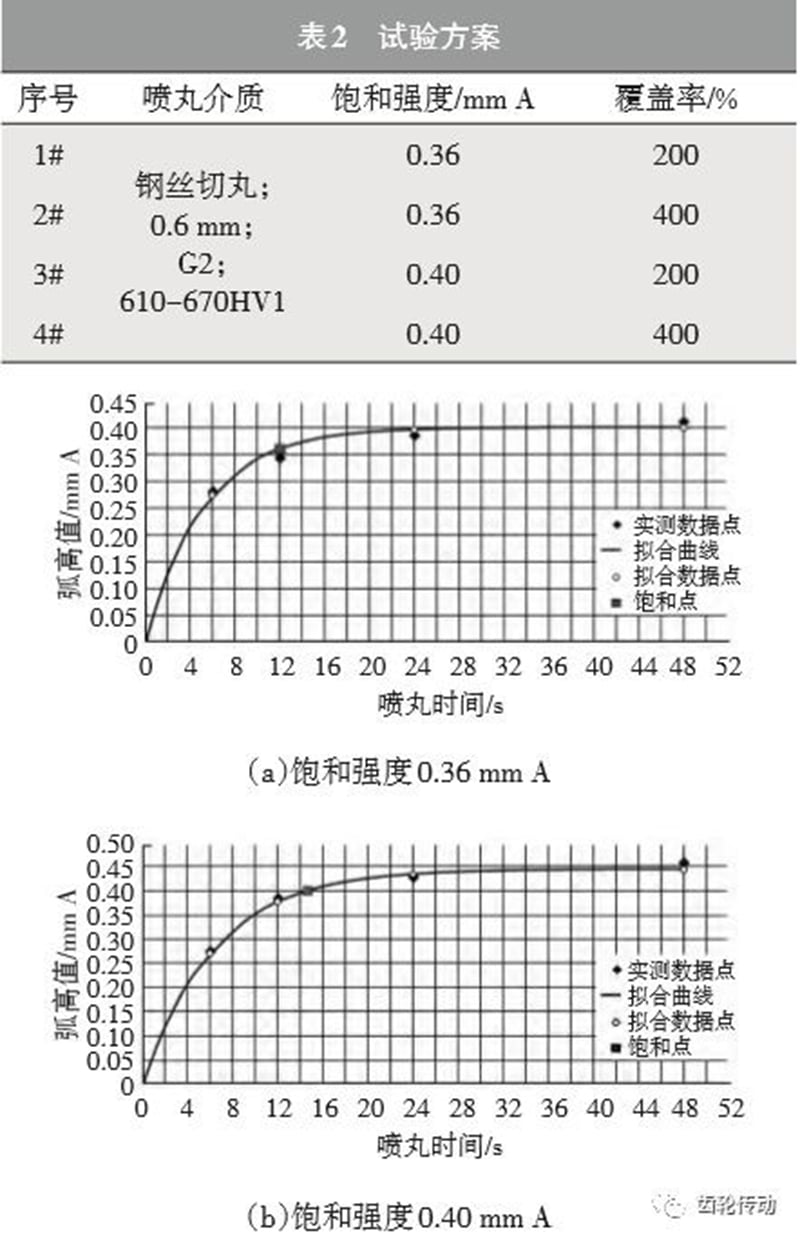

Siv lub tshuab compressed air shot peening hauv kev sim. Vim yog qhov xwm txheej ntawm kev sim, nws tsis tuaj yeem txheeb xyuas qhov cuam tshuam ntawm cov khoom siv shot peening (khoom siv, qhov loj me, qhov nyuaj). Yog li ntawd, cov khoom ntawm shot peening nruab nrab yog qhov ruaj khov hauv kev sim. Tsuas yog qhov cuam tshuam ntawm lub zog saturation thiab kev npog ntawm qhov roughness ntawm cov hniav tom qab shot peening thiaj li raug txheeb xyuas. Saib Rooj 2 rau cov qauv sim. Cov txheej txheem txiav txim siab tshwj xeeb ntawm cov kev ntsuas kev sim yog raws li nram no: kos cov kab saturation (Daim Duab 3) los ntawm Almen coupon test los txiav txim siab qhov saturation point, yog li xauv lub siab ntawm huab cua compressed, steel shot flow, nozzle txav ceev, nozzle nrug ntawm qhov chaw thiab lwm yam khoom siv.

qhov tshwm sim ntawm kev xeem

Cov ntaub ntawv txog qhov roughness ntawm cov hniav tom qab txhaj tshuaj peening tau qhia nyob rau hauv Rooj 3, thiab qhov tseeb ntawm cov hniav profile tau qhia nyob rau hauv Rooj 4. Nws tuaj yeem pom tias nyob rau hauv plaub qhov xwm txheej txhaj tshuaj peening, qhov roughness ntawm cov hniav nto nce ntxiv thiab cov kab nkhaus profile hniav dhau los ua concave thiab convex tom qab txhaj tshuaj peening. Qhov piv ntawm qhov roughness tom qab txau rau qhov roughness ua ntej txau yog siv los piav qhia txog qhov roughness magnification (Rooj 3). Nws tuaj yeem pom tias qhov roughness magnification txawv nyob rau hauv plaub qhov xwm txheej txheej txheem.

Kev Taug Qab Ua Ke ntawm Kev Loj Hlob ntawm Qhov Roughness ntawm Cov Hniav los ntawm Shot Peening

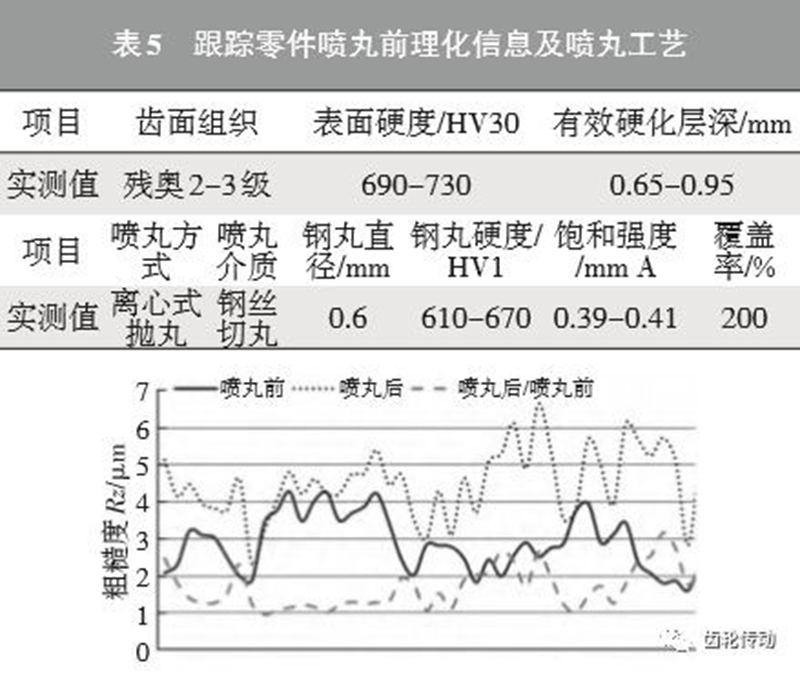

Cov txiaj ntsig ntawm kev xeem hauv Ntu 3 qhia tau tias qhov roughness ntawm cov hniav nce ntxiv ntau qib tom qab txhaj tshuaj peening nrog cov txheej txheem sib txawv. Yuav kom nkag siab tag nrho qhov kev nthuav dav ntawm txhaj tshuaj peening ntawm qhov roughness ntawm cov hniav thiab nce tus lej ntawm cov qauv, 5 yam khoom, 5 hom thiab 44 qhov tag nrho, tau raug xaiv los taug qab qhov roughness ua ntej thiab tom qab txhaj tshuaj peening raws li cov xwm txheej ntawm cov txheej txheem txhaj tshuaj peening ntau lawm. Saib Rooj 5 rau cov ntaub ntawv lub cev thiab tshuaj lom neeg thiab cov ntaub ntawv txheej txheem txhaj tshuaj peening ntawm cov khoom taug qab tom qab sib tsoo iav. Cov ntaub ntawv roughness thiab magnification ntawm cov hniav pem hauv ntej thiab tom qab ua ntej txhaj tshuaj peening tau pom hauv Daim Duab 4. Daim Duab 4 qhia tau tias qhov ntau ntawm qhov roughness ntawm cov hniav ua ntej txhaj tshuaj peening yog Rz1.6 μ m-Rz4.3 μ m; Tom qab txhaj tshuaj peening, qhov roughness nce ntxiv, thiab qhov faib tawm yog Rz2.3 μ m-Rz6.7 μ m; Qhov roughness siab tshaj plaws tuaj yeem nthuav dav txog 3.1 zaug ua ntej txhaj tshuaj peening.

Cov yam cuam tshuam rau qhov ntxhib ntawm cov hniav tom qab txhaj tshuaj peening

Los ntawm lub hauv paus ntsiab lus ntawm kev txhaj tshuaj peening, nws tuaj yeem pom tias qhov nyuaj siab thiab kev txav mus los ceev ceev tso ntau qhov av ntawm qhov chaw, uas yog qhov chaw ntawm kev ntxhov siab compressive seem. Tib lub sijhawm, cov qhov av no yuav ua rau qhov roughness ntawm qhov chaw nce ntxiv. Cov yam ntxwv ntawm cov khoom ua ntej txhaj tshuaj peening thiab cov txheej txheem txhaj tshuaj peening yuav cuam tshuam rau qhov roughness tom qab txhaj tshuaj peening, raws li teev nyob rau hauv Rooj 6. Hauv Ntu 3 ntawm daim ntawv no, nyob rau hauv plaub qhov xwm txheej txheej txheem, qhov roughness ntawm qhov chaw hniav tom qab txhaj tshuaj peening nce mus rau ntau qib sib txawv. Hauv qhov kev xeem no, muaj ob qhov hloov pauv, uas yog, pre-shot roughness thiab cov txheej txheem txheej txheem (saturation zog lossis kev npog), uas tsis tuaj yeem txiav txim siab qhov kev sib raug zoo ntawm post-shot peening roughness thiab txhua tus yam ntxwv cuam tshuam. Tam sim no, ntau tus kws tshawb fawb tau ua kev tshawb fawb txog qhov no, thiab muab tso rau pem hauv ntej ib qho qauv kwv yees theoretical ntawm qhov roughness ntawm qhov chaw tom qab txhaj tshuaj peening raws li finite element simulation, uas yog siv los kwv yees cov nqi roughness sib xws ntawm cov txheej txheem txhaj tshuaj peening sib txawv.

Raws li qhov kev paub dhau los thiab kev tshawb fawb ntawm lwm cov kws tshawb fawb, cov hom kev cuam tshuam ntawm ntau yam tuaj yeem kwv yees raws li qhia hauv Rooj 6. Nws tuaj yeem pom tias qhov roughness tom qab txhaj tshuaj peening yog cuam tshuam los ntawm ntau yam, uas kuj yog cov yam tseem ceeb uas cuam tshuam rau qhov seem compressive stress. Yuav kom txo qhov roughness tom qab txhaj tshuaj peening ntawm lub hauv paus ntawm kev ua kom muaj qhov seem compressive stress, ntau qhov kev sim txheej txheem yuav tsum tau ua kom zoo dua qhov kev sib xyaw ua ke.

Kev cuam tshuam ntawm qhov roughness ntawm cov hniav rau NVH kev ua tau zoo ntawm lub system

Cov khoom siv iav yog nyob rau hauv lub kaw lus kis tau tus mob dynamic, thiab qhov roughness ntawm cov hniav yuav cuam tshuam rau lawv cov kev ua tau zoo NVH. Cov txiaj ntsig ntawm kev sim qhia tau hais tias nyob rau hauv tib lub nra thiab qhov ceev, qhov ntau dua qhov roughness ntawm qhov chaw, qhov ntau dua qhov kev co thiab suab nrov ntawm lub kaw lus; Thaum lub nra thiab qhov ceev nce, qhov kev co thiab suab nrov nce ntxiv.

Nyob rau hauv xyoo tas los no, cov phiaj xwm ntawm cov tshuab txo zog tshiab tau nce sai, thiab qhia txog kev txhim kho ntawm kev kub ceev thiab lub zog loj. Tam sim no, lub zog siab tshaj plaws ntawm peb lub tshuab txo zog tshiab yog 354N · m, thiab qhov ceev tshaj plaws yog 16000r / min, uas yuav raug nce mus rau ntau dua 20000r / min yav tom ntej. Nyob rau hauv cov xwm txheej ua haujlwm zoo li no, qhov cuam tshuam ntawm kev nce ntawm qhov roughness ntawm cov hniav rau NVH kev ua tau zoo ntawm lub kaw lus yuav tsum tau xav txog.

Kev ntsuas kev txhim kho rau qhov ntxhib ntawm cov hniav tom qab txhaj tshuaj peening

Cov txheej txheem txhaj tshuaj peening tom qab sib tsoo iav tuaj yeem txhim kho lub zog qaug zog ntawm qhov chaw ntawm cov hniav iav thiab lub zog qaug zog ntawm cov hauv paus hniav. Yog tias cov txheej txheem no yuav tsum tau siv vim yog qhov laj thawj ntawm lub zog hauv cov txheej txheem tsim iav, txhawm rau xav txog kev ua haujlwm NVH ntawm lub kaw lus, qhov roughness ntawm qhov chaw ntawm cov hniav iav tom qab txhaj tshuaj peening tuaj yeem txhim kho los ntawm cov hauv qab no:

a. Ua kom zoo dua cov txheej txheem txhaj tshuaj peening, thiab tswj qhov kev nthuav dav ntawm qhov roughness ntawm cov hniav tom qab txhaj tshuaj peening ntawm lub hauv paus ntawm kev ua kom muaj kev ntxhov siab compressive seem. Qhov no xav tau ntau qhov kev sim txheej txheem, thiab cov txheej txheem versatility tsis muaj zog.

b. Cov txheej txheem sib xyaw ua ke tau txais yuav, uas yog, tom qab ua tiav qhov muaj zog ib txwm muaj, ntxiv lwm qhov kev sib xyaw ua ke. Lub zog ntawm cov txheej txheem sib xyaw ua ke feem ntau me me. Hom thiab qhov loj ntawm cov khoom siv sib xyaw ua ke tuaj yeem hloov kho, xws li cov khoom siv ceramic, cov khoom siv iav lossis cov khoom siv hlau txiav nrog qhov me me.

c. Tom qab txhaj tshuaj peening, cov txheej txheem xws li kev txhuam hniav thiab kev txhuam dawb raug ntxiv.

Hauv tsab ntawv no, kev kawm txog qhov roughness ntawm cov hniav ntawm cov txheej txheem shot peening sib txawv thiab cov khoom sib txawv ua ntej thiab tom qab shot peening, thiab cov lus xaus hauv qab no tau kos raws li cov ntaub ntawv sau:

◆ Kev siv tshuab shot peening yuav ua rau qhov roughness ntawm cov hniav nce ntxiv, uas cuam tshuam los ntawm cov yam ntxwv ntawm cov khoom ua ntej siv tshuab shot peening, cov txheej txheem shot peening thiab lwm yam, thiab cov yam no kuj yog cov yam tseem ceeb uas cuam tshuam rau qhov kev ntxhov siab seem;

◆ Raws li cov txheej txheem tsim khoom uas twb muaj lawm, qhov roughness ntawm cov hniav tom qab shot peening yog 3.1 npaug ntawm ua ntej shot peening;

◆ Qhov nce ntawm qhov ntxhib ntawm cov hniav yuav ua rau lub cev muaj zog thiab suab nrov ntxiv. Lub zog loj dua thiab qhov ceev dua, qhov pom tseeb dua qhov nce ntawm kev co thiab suab nrov;

◆ Qhov roughness ntawm cov hniav tom qab shot peening tuaj yeem txhim kho tau los ntawm kev ua kom zoo dua cov txheej txheem shot peening, composite shot peening, ntxiv polishing lossis free honing tom qab shot peening, thiab lwm yam. Kev ua kom zoo dua ntawm cov txheej txheem shot peening yuav tswj tau qhov roughness amplification mus txog li 1.5 npaug.

Lub sijhawm tshaj tawm: Kaum Ib Hlis-04-2022