Siab zog Bevel Gearsyog qhov kev xaiv zoo tshaj yog tias koj tab tom nrhiav kev txhim khu kev qha thiab raug 90 degree kis tau tus mob. Ua los ntawm cov khoom zoo 45 # steel, cov iav no ruaj khov thiab tsim los muab kev siv hluav taws xob ntau tshaj plaws thiab raug.

Rau cov ntawv thov kev lag luam uas xav tau qhov tseeb thiab txhim khu kev qha 90-degree kis tau tus mob,high-strength bevel iavyog cov tshuaj zoo tagnrho. Cov iav no tau raug tsim los ua kom ntseeg tau tias qhov ua tau zoo tshaj plaws thiab ua kom muaj kev ua haujlwm zoo thiab ua haujlwm zoo.

Txawm hais tias koj tab tom tsim cov tshuab lossis ua haujlwm ntawm cov khoom siv, cov iav bevel no zoo meej. Lawv yooj yim rau nruab thiab khiav lag luam, thiab tuaj yeem tiv taus txawm tias muaj kev lag luam hnyav tshaj plaws.

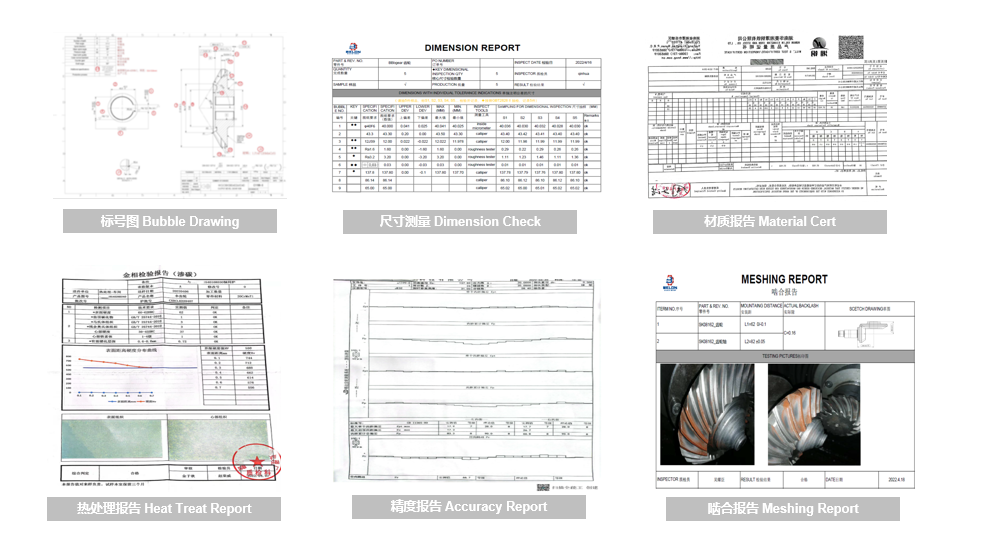

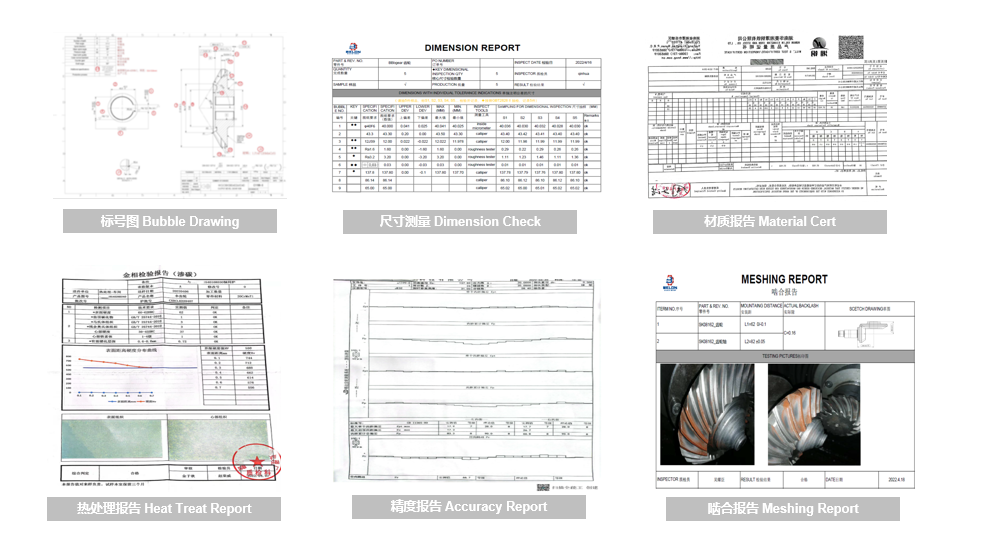

Yuav ua li cas cov ntaub ntawv yuav muab rau cov neeg muas zaub ua ntej shipping rau sib tsoo loj kauv bevel iav?

1) npuas kos duab

2) Dimension daim ntawv qhia

3) Cov ntaub ntawv pov thawj

4) Daim ntawv qhia txog kev kho cua sov

5) Ultrasonic Test Report (UT)

6) Sib Nqus Particle Test Report (MT)

Meshing test report