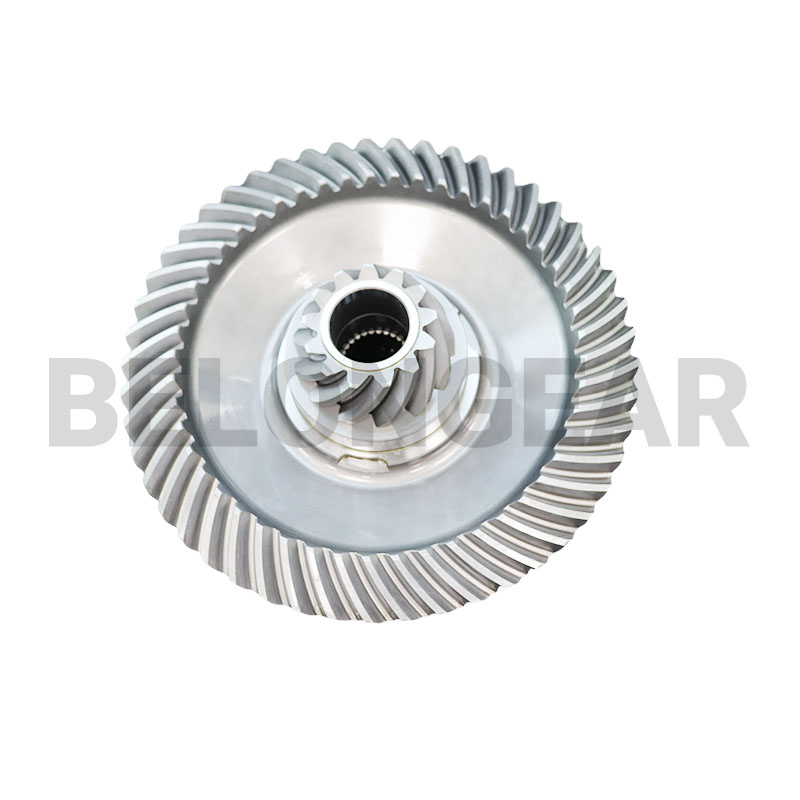

Paub txog kev ua haujlwm tsis muaj teeb meem thiab kev ua tau zoo dua nrog peb lub Spline Integrated Bevel Gear. Txawm hais tias koj tab tom daws cov haujlwm hnyav lossis cov txheej txheem kho tshuab nyuaj, ntseeg siab rau peb cov iav daws teeb meem los tsa koj daim ntawv thov mus rau qib tshiab ntawm kev raug thiab kev ntseeg siab.

Nyob rau hauv lub caij nyoog ntawm kev sib txuas lus thev naus laus zis, peb nkag siab txog qhov tseem ceeb ntawm kev sib txuas thiab kev ua haujlwm ntse. Peb cov iav systems yog tsim los nrog kev sib raug zoo hauv siab, seamlessly integrate nrog digital saib xyuas thiab tswj systems. Qhov kev sib txuas no tsis yog tsuas yog txhim kho kev yooj yim ntawm kev siv tab sis kuj pab txhawb kev saib xyuas kwv yees, txo downtime thiab txhim kho tag nrho cov system efficiency.

Ua ib feem ntawm peb txoj kev cog lus rau kev tswj xyuas zoo, peb siv cov txheej txheem kuaj xyuas nruj thoob plaws hauv cov txheej txheem tsim khoom. Qhov no lav tias txhua lub iav system tawm hauv peb cov chaw ua raws li cov qauv siab tshaj plaws, pab txhawb rau lub koob npe nrov rau kev ntseeg tau thiab kev sib xws.

Cov ntawv qhia txog hom twg yuav muab rau cov neeg siv khoom ua ntej xa khoom rau kev sib tsoo lojcov iav bevel spiral ?

1. Kos duab npuas

2. Daim ntawv qhia txog qhov ntev

3. Daim ntawv pov thawj khoom siv

4. Daim ntawv qhia txog kev kho cua sov

5. Daim ntawv qhia txog kev xeem Ultrasonic (UT)

6. Daim ntawv qhia txog kev xeem sib nqus (MT)

Daim ntawv qhia txog kev sim meshing

Peb muaj thaj tsam ntawm 200000 square meters, thiab peb kuj muaj cov khoom siv tsim khoom thiab tshuaj xyuas ua ntej kom tau raws li cov neeg siv khoom xav tau. Peb tau qhia txog qhov loj tshaj plaws, thawj lub iav tshwj xeeb Gleason FT16000 tsib-axis machining center txij li thaum Gleason thiab Holler tau koom tes.

→ Txhua Lub Modules

→ Txhua Tus Naj Npawb ntawm Cov Hniav Gears

→ Qhov tseeb siab tshaj plaws DIN5-6

→ Kev ua haujlwm siab, kev ua haujlwm siab

Nqa qhov kev npau suav tsim khoom, kev ywj pheej thiab kev lag luam rau cov khoom me me.

Kev ntaus nrig

Tshuab dhos

Kev Sib Tsoo

Kev kho cua sov

Kev sib tsoo OD / ID

Kev txhuam